Custom Shutter Patti Production Machine for Efficient Manufacturing Solutions

The Custom Shutter Patti Making Machine Revolutionizing Window Treatments

In the ever-evolving world of interior design and home improvement, the demand for customizable solutions has never been higher. Among the myriad of options available, shutters remain a popular choice for both aesthetic appeal and functional benefits. The introduction of the custom shutter patti making machine has transformed the way shutters are manufactured and customized, providing a competitive edge in the market while meeting the unique preferences of consumers.

Understanding the Shutter Patti

Shutter pattis, or slats, are the individual components that make up shutter systems, allowing for light control, ventilation, and privacy. Traditional shutters are often made from wood or composite materials, but there is an increasing trend towards using sustainable materials such as recycled plastics and metals. The versatility of shutter pattis means they can be designed in various styles, colors, and configurations, catering to both contemporary and classic interior designs.

Evolution of Shutter Manufacturing

Historically, manufacturing shutters has been a labor-intensive process, involving manual cutting, shaping, and painting. While artisans have traditionally brought skill and artistry to shutter-making, this method has limitations, particularly in speed and customization. The introduction of the custom shutter patti making machine automates much of this process, significantly reducing production time and allowing manufacturers to create highly customized products.

The Custom Shutter Patti Making Machine

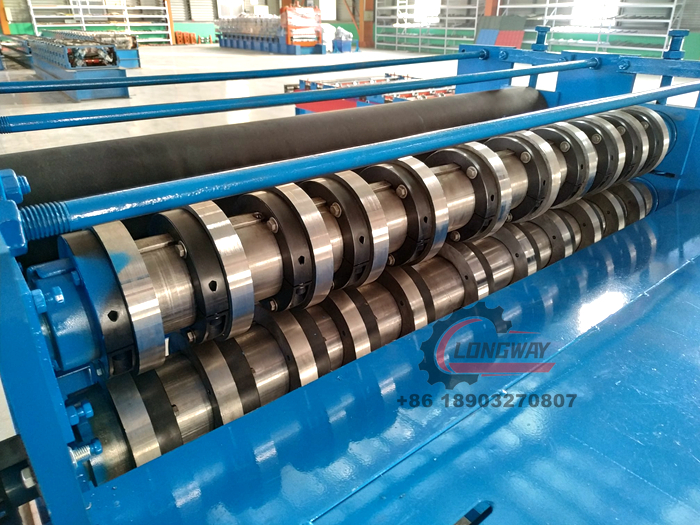

The custom shutter patti making machine is designed to streamline the production of shutter components. Equipped with advanced technology, these machines utilize precision cutting, CNC routing, and automated assembly systems. The key features of this machine include

1. Precision Cutting The machine uses laser or rotary cutting techniques, ensuring that each patti is cut to exact specifications without wastage, maintaining high levels of consistency across multiple units.

custom shutter patti making machine

2. Material Versatility It can handle a variety of materials, including wood, composite, and eco-friendly alternatives, allowing manufacturers to diversify their product offerings.

3. Customization Options The machine can easily be programmed to create pattis in different sizes, shapes, and styles. Customers can choose from various finishes and colors, thus creating a truly bespoke product.

4. Efficiency and Speed The automation provided by the machine significantly reduces the time taken to produce each shutter patti, enabling manufacturers to meet higher demands without compromising on quality.

5. Integration Capabilities Many modern shutter patti making machines can be integrated into existing manufacturing lines, making the transition smoother for businesses looking to update their operations.

Benefits for Manufacturers and Consumers

The adoption of custom shutter patti making machines yields substantial benefits for both manufacturers and consumers. For manufacturers, the ability to produce high-quality, customized products quickly enhances their competitiveness in the market. Furthermore, the reduction in labor costs due to automation allows for better price points without sacrificing profit margins.

For consumers, the increased availability of customizable options means that they can achieve their desired aesthetic without compromise. Whether renovating a home or designing a new space, the flexibility of the custom shutter patti allows for tailoring that fits individual tastes. Additionally, the quality of the finished products is often superior, given the precision of machine manufacturing.

Conclusion

The custom shutter patti making machine represents a significant advancement in the shutter manufacturing industry. As the trend toward customization grows, embracing such technology provides manufacturers with the tools needed to meet consumer demands effectively. The ability to create unique shutters that enhance the beauty and functionality of a space not only benefits the industry but also contributes to the satisfaction of homeowners. In a world where personal expression through design is paramount, innovations like these pave the way for a brighter, more customized future in window treatments.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025