Custom Sheet Metal Roofing Equipment for Precision Roofing Solutions

Custom Sheet Metal Roofing Machines Revolutionizing the Roofing Industry

In the roofing industry, the demand for customized solutions has surged in recent years, driven by advancements in technology and changing consumer preferences. Among the myriad of innovations, custom sheet metal roofing machines stand out as a game-changer, offering unparalleled precision, efficiency, and flexibility. These machines not only streamline the production process but also empower roofing contractors and manufacturers to meet specific client needs with ease.

What are Custom Sheet Metal Roofing Machines?

Custom sheet metal roofing machines are specialized equipment designed to fabricate and shape metal sheets into various roofing profiles. Unlike traditional machines that produce standard sizes and shapes, these custom machines allow for tailored outputs based on project specifications. This adaptability is crucial for tackling unique architectural designs and fulfilling individual customer requirements, thereby enhancing overall service quality in the roofing market.

Key Features and Benefits

1. Precision and Accuracy Modern custom sheet metal roofing machines utilize advanced technology, such as computer numerical control (CNC), to achieve remarkable precision. This ensures that every piece of metal roofing fits perfectly, reducing material wastage and minimizing installation time. Precision is particularly critical in metal roofing, where even minor discrepancies can lead to significant issues during installation.

2. Versatility These machines can produce a wide array of roofing profiles, from standing seam roofs to corrugated panels and beyond. Roofing contractors can easily switch between designs, allowing them to cater to various projects without the need for multiple machines. This versatility enables businesses to grow and diversify their service offerings, attracting a broader clientele.

3. Efficiency and Speed Custom sheet metal roofing machines are designed to operate at high speeds without compromising quality. This efficiency translates to faster turnaround times for projects, which is essential in today’s competitive market. Contractors can complete more jobs in less time, thereby increasing their profitability.

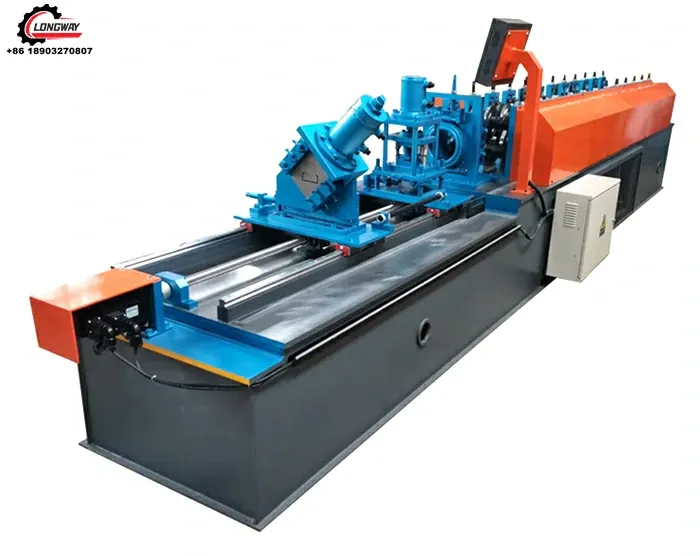

custom sheet metal roofing machine

4. Material Flexibility The machines can work with a variety of metal types, including steel, aluminum, copper, and zinc. This flexibility allows roofing contractors to provide clients with a range of material options, each with its own aesthetic and functional benefits. Tailoring materials to match the client’s vision is crucial in creating a successful roofing solution.

5. Cost-Effective Solutions By eliminating the need for intermediate manufacturing processes and reducing material waste, custom sheet metal roofing machines offer significant cost savings. Contractors can pass these savings on to their clients, making custom roofing solutions a more attractive option.

Applications in the Roofing Industry

The applications of custom sheet metal roofing machines are extensive. They are ideal for both residential and commercial roofing projects, providing solutions for new construction as well as repair and renovation work. Whether it is a unique custom home that requires intricate detailing or a commercial building that necessitates durable, long-lasting roofing, these machines are equipped to handle the challenges.

Furthermore, with the growing emphasis on sustainability in construction, metal roofing has become increasingly popular due to its longevity and recyclability. Custom sheet metal roofing machines support this trend by allowing manufacturers to create energy-efficient roofing solutions that not only meet but exceed industry standards.

Conclusion

As the roofing industry continues to evolve, custom sheet metal roofing machines represent a significant leap forward. They provide roofing contractors with the tools necessary to meet the growing demand for personalized, high-quality roofing solutions. By embracing these innovative machines, businesses can enhance their operational efficiency, improve accuracy, and ultimately deliver superior products to their clients. In an era where customization is key, investing in custom sheet metal roofing machines is not just a smart decision; it is a necessity for standing out in a competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025