custom sheet metal roll forming machines

Custom Sheet Metal Roll Forming Machines Revolutionizing Manufacturing

In the realm of manufacturing, efficiency and precision are paramount. As industries evolve, the demand for customized solutions has never been greater. Custom sheet metal roll forming machines have emerged as game-changers, enabling businesses to produce complex shapes and components with unparalleled accuracy and speed. This article delves into the significance of these machines, their applications, and their advantages in modern manufacturing processes.

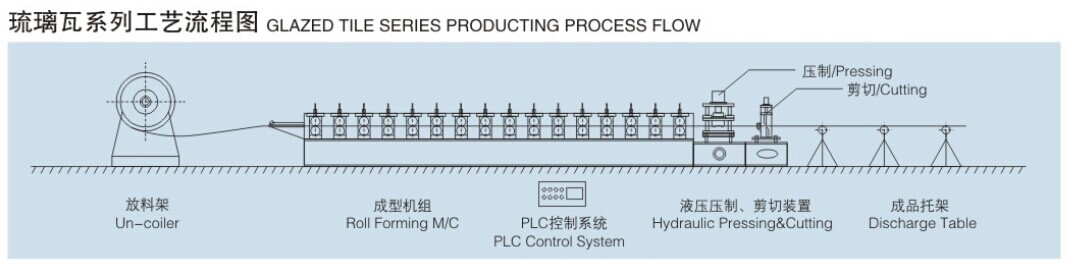

Understanding Sheet Metal Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically sheet metal, is passed through a series of rollers. Each roller progressively shapes the metal into the desired profile, making it an ideal method for producing long lengths of uniform cross-section components. This process is highly beneficial for creating products such as roof panels, wall studs, and automotive parts.

The Need for Customization

Every industry has unique requirements that often demand specific shapes and sizes that cannot be efficiently produced with standard machines. Custom sheet metal roll forming machines cater to this need by allowing for tailored designs. Manufacturers can work closely with clients to develop specialized profiles that meet their particular specifications, which can lead to enhanced product performance and reduced material waste.

Key Features of Custom Roll Forming Machines

Custom sheet metal roll forming machines are equipped with advanced technologies that contribute to their efficacy

. Key features include1. Versatility These machines can be designed to accommodate a variety of materials including steel, aluminum, and copper, allowing for increased flexibility in production.

custom sheet metal roll forming machines

2. Precision Engineering With sophisticated controls and software, these machines provide precise dimensional accuracy, resulting in high-quality finished products.

3. Automation Many custom roll forming machines can be fully automated, reducing labor costs and minimizing human error. This automation enhances production speed and efficiency.

4. Adaptability Custom machines can be adapted to different production processes, such as integrating welding or punching, to meet diverse manufacturing needs in a single run.

Applications Across Industries

Custom sheet metal roll forming machines find applications across numerous sectors. In the construction industry, they are used to create structural components, roofing materials, and decorative elements. The automotive industry benefits from these machines by producing framing components and body parts that require specific tolerances. Additionally, the energy sector employs custom roll forming for producing parts used in solar panels and wind turbines.

Advantages of Custom Roll Forming Machines

The advantages of using custom sheet metal roll forming machines are manifold. Firstly, they significantly reduce material waste by ensuring that sheets are optimally utilized. This not only leads to cost savings but also aligns with sustainable manufacturing practices. Secondly, the ability to create complex shapes that would be challenging to produce through other methods provides a competitive edge in product design. Finally, the scalability of roll forming processes means that manufacturers can easily adjust their production volumes to meet changing demands.

Conclusion

In conclusion, custom sheet metal roll forming machines play a crucial role in the modern manufacturing landscape. Their ability to deliver precision, customization, and efficiency makes them invaluable across a multitude of industries. As technology continues to advance, the future of roll forming looks promising, offering even more innovative solutions to meet the ever-evolving manufacturing needs. Embracing these advancements is essential for businesses looking to enhance their productivity and stay ahead in a competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025