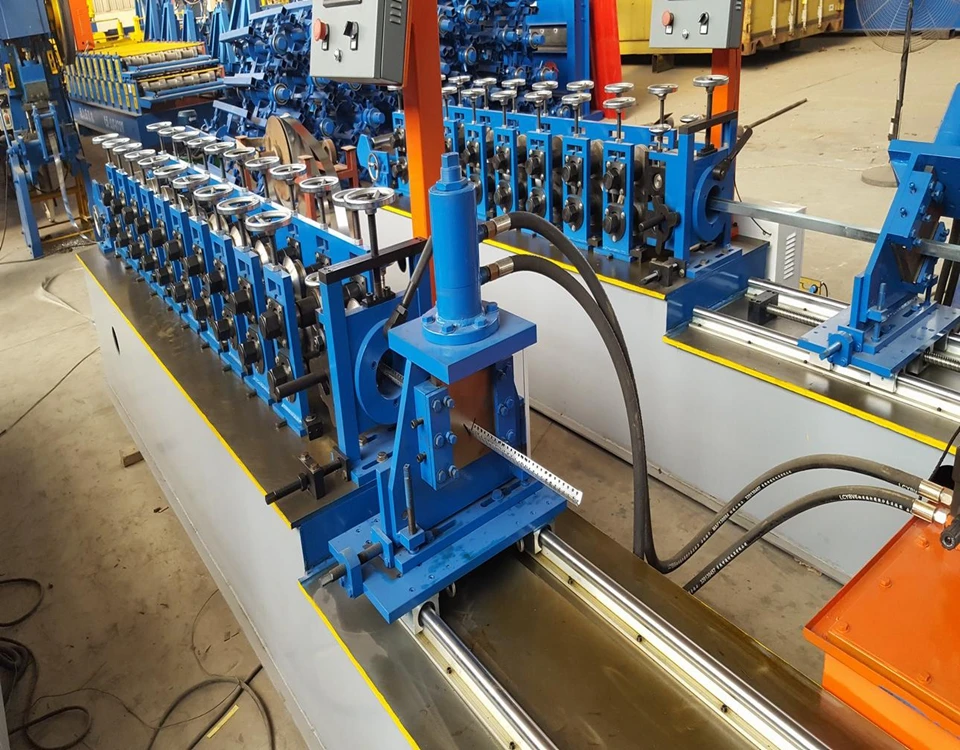

custom sheet metal roll forming machines

Custom Sheet Metal Roll Forming Machines Revolutionizing Manufacturing

In the ever-evolving landscape of manufacturing, custom sheet metal roll forming machines have become indispensable tools for producing high-quality metal components with precision and efficiency. These machines are revolutionizing the way various industries—such as construction, automotive, aerospace, and appliances—handle metal fabrication. From creating complex profiles to producing sheets in large volumes, roll forming technology is the backbone of many modern manufacturing processes.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of sheet metal is progressively shaped into a desired cross-section. By passing the metal strip through a series of rollers, the sheet is gradually formed into the required profile, whether it be channels, angles, or other complex shapes. This method is particularly beneficial for producing consistent, repeatable forms with minimal waste, making it highly efficient compared to traditional cutting and welding methods.

Advantages of Customization

One of the most significant advantages of custom sheet metal roll forming machines lies in their ability to produce tailored components. Manufacturers can design roll forming machines specifically to meet their unique requirements, allowing for the creation of bespoke metal products that fit project specifications perfectly. This customization extends to several aspects, including

1. Material Type Custom roll forming machines can handle a variety of materials, including aluminum, stainless steel, and galvanized steel. This versatility enables manufacturers to select the best materials for their applications.

2. Profile Complexity Custom machines can be engineered to form intricate and complex profiles that are often difficult to achieve with standard equipment. This capability is paramount for industries requiring specialized components, such as reinforced metal sections in construction or structural elements in the automotive sector.

3. Production Volume With the ability to scale production, manufacturers can specify the speed and capabilities of their roll forming machines to align with their production goals, whether low-volume bespoke runs or high-volume mass production.

4. Precision and Consistency High-quality roll forming machinery can produce components with tight tolerances and minimal variations. This precision is essential for industries where even slight deviations can lead to major issues down the line, such as in the aerospace or automotive sectors.

The Roll Forming Process

The roll forming process typically involves several stages, including material feeding, roll forming, cutting, and finishing

. Here's a breakdown of these stagescustom sheet metal roll forming machines

1. Material Feeding The process begins with the feeding of a coil or strip of metal into the machine. The metal is unwound and fed into the series of rollers.

2. Roll Forming As the metal strip passes through the rollers, it undergoes continuous bending until it reaches the desired cross-sectional shape.

3. Cutting to Length Once the desired profile is formed, it is cut to the required lengths using various cutting methods, such as flying cuts or shearing.

4. Finishing The final products may undergo treatments such as coating, painting, or polishing to ensure they meet industry standards and customer specifications.

Applications of Custom Roll Forming Machines

The applications for custom sheet metal roll forming machines span a wide array of industries. For example

- Construction Roll formed metal components are widely used in roofing, siding, and framing systems. These components offer strength and durability while ensuring aesthetic appeal.

- Automotive Roll forming is crucial for manufacturing parts like door frames, bumpers, and chassis components, providing a combination of strength and lightweight properties.

- Aerospace In the aerospace sector, roll forming is utilized for producing sophisticated components that require both high strength-to-weight ratios and precise dimensions.

- Home Appliances Many household appliances are manufactured using roll formed metal parts, which contribute to their structural integrity and overall functionality.

Conclusion

Custom sheet metal roll forming machines have ushered in a new era in manufacturing, offering unparalleled advantages in efficiency, precision, and versatility. As industries continue to evolve, the demand for customized solutions will only grow, reinforcing the significance of roll forming technology in meeting the diverse needs of modern manufacturing. Whether it’s for large-scale production or bespoke projects, custom roll forming machines enable manufacturers to innovate and excel in an increasingly competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025