custom sheet metal roll forming

Custom Sheet Metal Roll Forming Revolutionizing Manufacturing

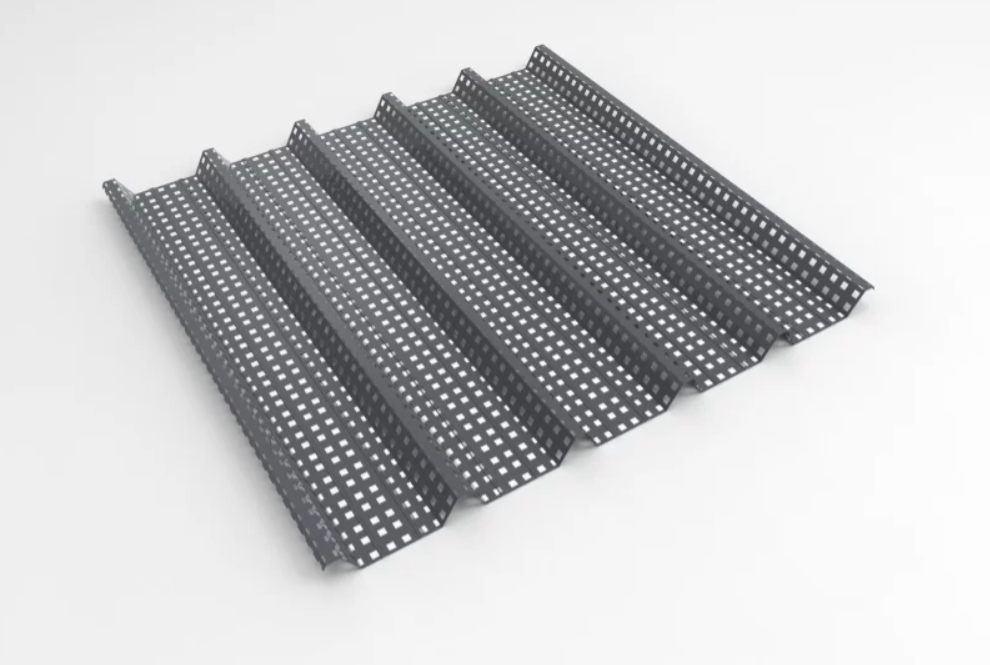

In today's competitive manufacturing landscape, custom sheet metal roll forming has emerged as a pivotal process for producing high-quality, precision-engineered metal components. This innovative technique involves the continuous bending of metal sheets into desired shapes and profiles, making it an essential method for a wide range of industries, including construction, automotive, and aerospace.

The roll forming process begins with feeding a flat strip of metal, typically made from materials like steel or aluminum, through a series of rollers. Each roller incrementally shapes the metal, allowing for the creation of complex profiles with tight tolerances. This method is not only efficient but also minimizes material waste, as it utilizes the entire sheet and can produce long continuous lengths of parts, which can be cut to size later.

One of the most significant advantages of custom sheet metal roll forming is its versatility. Manufacturers can create a vast array of shapes and sizes tailored to specific applications. From automotive brackets to roofing panels, the ability to customize designs ensures that companies can meet precise specifications and customer requirements. Moreover, advanced technology and computer-aided design (CAD) software allow for rapid prototyping and design adjustments, further enhancing the customization process.

custom sheet metal roll forming

Durability is another critical factor that makes roll-formed metal components favorable in various applications. The continuous formation process leads to enhanced structural integrity and increased strength, providing products that withstand extreme conditions and heavy loads. Additionally, the surface finish of roll-formed components can be easily enhanced through processes like galvanizing or powder coating, offering added protection against corrosion and wear.

Cost-effectiveness is an essential consideration for manufacturers, and custom sheet metal roll forming often proves to be a financially sensible choice. Although the initial setup costs can be higher due to specialized tooling, the long-term efficiency gained from high production rates and minimal waste typically results in lower per-unit costs. Businesses can achieve significant savings, making this method an attractive option for large-scale production runs.

As industries continue to evolve and the demand for customized solutions grows, custom sheet metal roll forming stands out as a formidable solution. Its combination of design flexibility, strength, and efficiency positions it as a driving force in modern manufacturing. Companies looking to innovate their production processes would do well to consider the advantages of roll forming, as it offers a pathway to not only meet but exceed customer expectations in today's dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025