Top Suppliers of Custom Roof Sheet Manufacturing Machines You Can Trust

Custom Roof Sheet Making Machine Suppliers A Comprehensive Guide

In the ever-evolving construction industry, the demand for high-quality roofing materials has led to a surge in the adoption of custom roof sheet making machines. These machines play a crucial role in producing roof sheets that meet specific requirements, both in terms of design and durability. As a result, suppliers of these machines are increasingly important players in the market, contributing to the efficiency and quality of roofing projects worldwide.

Understanding Custom Roof Sheet Making Machines

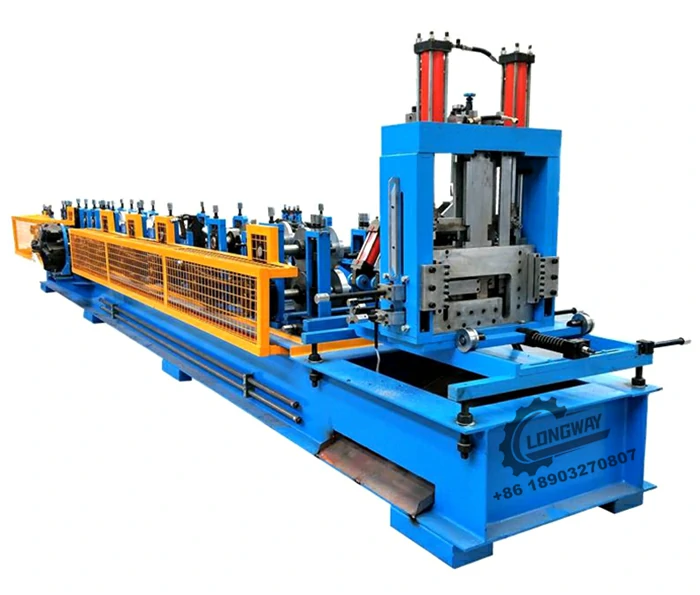

Custom roof sheet making machines are specialized equipment used to produce roofing sheets customized to various specifications. These machines can create sheets in different shapes, sizes, and materials, including steel, aluminum, and plastic. The production process typically involves several stages, including metal forming, cutting, and finishing, resulting in a final product that is ready for installation.

One of the primary advantages of using a custom roof sheet making machine is the ability to produce sheets that cater to specific client needs. For instance, a contractor may require sheets that can withstand extreme weather conditions, have particular aesthetic qualities, or conform to local building codes. Custom machines can be tailored to meet these specifications, providing a significant competitive edge in the roofing market.

The Role of Suppliers

Suppliers of custom roof sheet making machines are instrumental in facilitating the manufacturing process for construction companies. They provide not only the machines themselves but also offer essential support services, including installation, maintenance, and technical training. This support is particularly valuable for businesses that may not have extensive experience operating such specialized equipment.

When sourcing a machine, several factors come into play, including the supplier's reputation, the quality of the machines offered, and the level of after-sales support provided. It is essential for construction firms to invest time in researching potential suppliers to ensure they are selecting a partner that aligns with their operational needs and quality standards.

Key Features to Look for in Custom Roof Sheet Making Machines

When considering which custom roof sheet making machine to invest in, several key features should be evaluated

custom roof sheet making machine suppliers

2. Automation Level Automated machines can increase production speed and reduce labor costs, making them an attractive option for businesses looking to scale their operations.

3. Precision and Accuracy The machinery must be capable of producing sheets that meet precise specifications to ensure quality and durability in the final product.

4. Ease of Use Machines that come with user-friendly interfaces and clear operating instructions can significantly reduce training time for staff.

5. After-Sales Support Comprehensive support for maintenance, repairs, and spare parts will ensure that the machine continues to operate efficiently over its lifespan.

The Future of Custom Roof Sheet Making

The future looks promising for custom roof sheet making machine suppliers. As the construction industry continues to grow, there will be a sustained demand for innovative roofing solutions that are both aesthetically pleasing and functional. With advancements in technology, machine manufacturers are likely to introduce smarter, more efficient machines that incorporate features such as IoT connectivity, enhancing operational efficiency and tracking.

Moreover, the growing emphasis on sustainability will likely influence the market. Suppliers who incorporate eco-friendly technologies and materials into their machines may find themselves at a competitive advantage as more companies seek to reduce their environmental footprint.

Conclusion

In conclusion, custom roof sheet making machine suppliers play a vital role in the construction industry, providing essential equipment and support to meet the increasing demand for bespoke roofing solutions. By understanding the various considerations involved in selecting a supplier and the features that define a quality machine, construction firms can enhance their operational capabilities and ensure they are well-equipped to tackle future projects. The investment in custom roof sheet making machines is not just a choice but a strategic move towards improved efficiency and quality in roofing production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025