Affordable Custom Roofing Sheet Roll Forming Machines for Sale

The Cost of Custom Roofing Sheet Roll Forming Machines

In the realm of modern construction, the demand for efficient and cost-effective solutions is ever-increasing. Among these solutions, custom roofing sheet roll forming machines have become a staple in the roofing industry. These machines are designed to create roofing sheets with precision and speed, catering to the unique specifications of various projects. However, a key consideration for businesses looking to invest in this technology is the price of these machines.

The price of custom roofing sheet roll forming machines can vary significantly based on several factors. First and foremost, the complexity of the machine plays a critical role in determining its cost. Basic models may be priced lower due to their straightforward designs, while advanced machines equipped with features like programmable controls, higher production speeds, and the ability to handle multiple material types tend to be more expensive. Businesses must balance their production needs with budget constraints to find the right machine.

Material selection is another influential factor. The choice of metals, such as galvanized steel, aluminum, or copper, can impact both the performance of the machine and the quality of the finished product. High-quality materials often lead to higher costs but may yield better durability and efficiency in the long run. Discussing these aspects with suppliers can provide insight into the best material choices for specific applications.

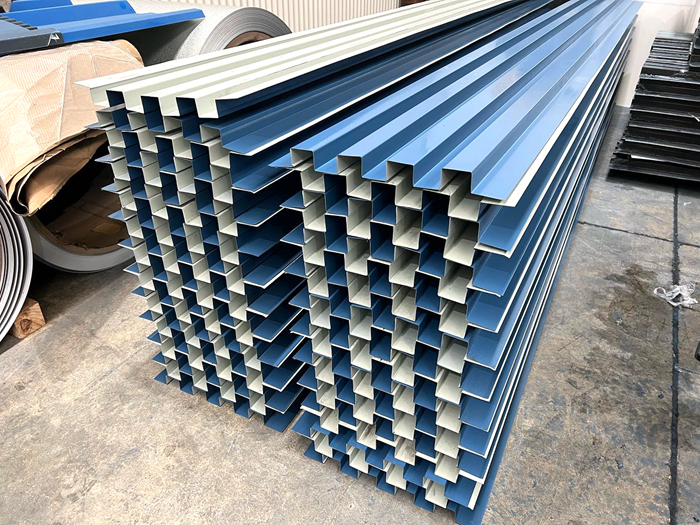

custom roofing sheet roll forming machine price

Additionally, customization options can also affect pricing. Many manufacturers offer machines that can be tailored to produce specific designs or sizes, which can lead to increased costs. However, these custom solutions often provide greater flexibility and can enhance a business's competitive edge by allowing them to meet diverse customer demands.

It’s also essential to factor in the total cost of ownership, which includes maintenance, operational costs, and the longevity of the machine. An initial lower price may be appealing, but if the machine requires frequent repairs or has limited operational life, the overall expenses can quickly add up.

In conclusion, while the price of custom roofing sheet roll forming machines can vary based on complexity, materials, and customization options, investing in the right equipment is crucial for efficiency and long-term success in the roofing industry. Businesses should carefully assess their needs and budget to make an informed decision that will benefit them for years to come. By doing so, they can ensure they are not only making a wise financial investment but also enhancing their operational capabilities in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025