Custom Roof Batten Roll Former for Efficient Construction Solutions

Custom Roof Batten Roll Forming Machine A Comprehensive Overview

In the realm of modern construction and roofing, efficiency, durability, and adaptability are crucial. One of the essential components that contribute significantly to these requirements is the roof batten, which serves as a supporting element in roofing systems. To meet the diverse demands of the construction industry, the custom roof batten roll forming machine has emerged as a vital technological innovation.

Understanding Roof Battens

Roof battens are horizontal strips used to support roof coverings such as tiles or metal sheets. They play a pivotal role in fastening materials securely while providing ventilation and water drainage. The quality and accuracy of these battens are critical, which is where roll forming technology becomes indispensable.

What is a Roll Forming Machine?

A roll forming machine is a manufacturing tool that uses continuous bending of strips of metal into a desired profile. It operates by passing the metal strip through a series of rollers that progressively shape it into the final form. The primary advantage of using roll forming is its efficiency in producing uniform parts that can be customized to meet specific requirements.

Customization in Roll Forming

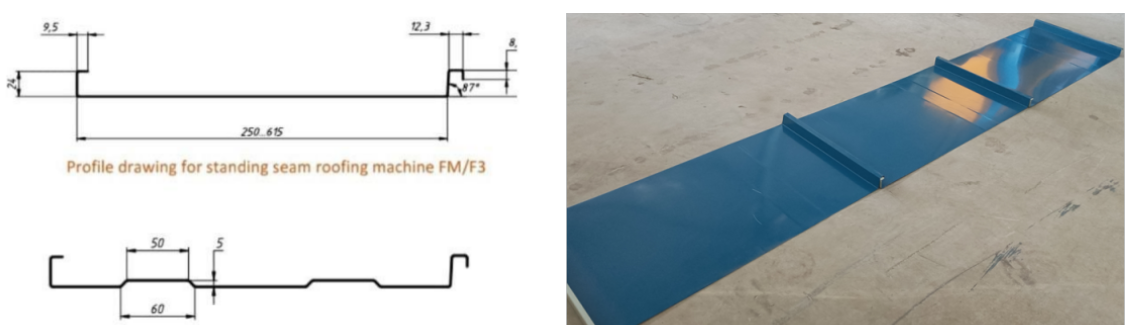

The term custom in custom roof batten roll forming machine indicates its ability to produce battens tailored to unique specifications. This flexibility is vital for contractors and builders who need roof battens that fit specific architectural designs or project needs. Custom configurations can include different dimensions, thicknesses, and profiles, ensuring that the final product meets precise standards.

custom roof batten roll forming machine

Advantages of Custom Roof Batten Roll Forming Machines

1. Efficiency These machines significantly reduce production time compared to traditional methods. With high-speed operations, manufacturers can produce large volumes of battens quickly, thereby meeting the urgent demands of construction projects.

2. Precision Custom roof batten roll forming machines offer high levels of accuracy in production. The automated nature of the machinery ensures consistent quality, reducing the chances of defects that can occur in manual processes.

3. Reduced Material Waste Roll forming is known for its material efficiency. The process produces less scrap compared to other forming techniques, allowing businesses to minimize waste and lower material costs.

4. Versatility These machines are capable of producing a wide range of batten profiles, making them suitable for various roofing applications—from residential homes to commercial buildings.

5. Durability Roof battens produced by roll forming machines are typically made from high-strength materials, ensuring longevity and resistance to environmental factors such as moisture and UV exposure.

Conclusion

The custom roof batten roll forming machine is a game-changer in the construction industry, providing a blend of efficiency, precision, and customization that meets the needs of modern roofing projects. As the demand for durable and adaptable roofing solutions grows, investing in this technology becomes essential for manufacturers looking to thrive in a competitive market. By embracing this advanced machinery, businesses can ensure superior quality in their roofing components while enhancing overall productivity and profitability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025