Custom Steel Roll Forming Solutions for Unique Project Needs and Specifications

Custom Roll Forming Steel An Innovative Approach to Metal Fabrication

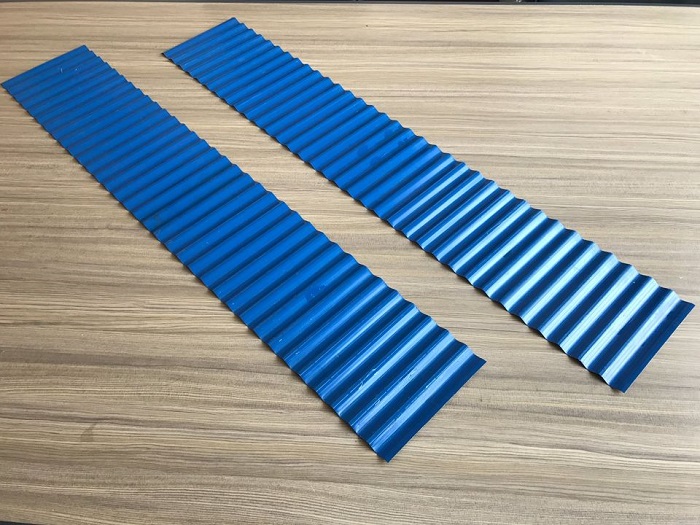

In the realm of metal fabrication, custom roll forming steel has emerged as a highly effective and versatile technique that is revolutionizing the industry. By converting flat metal sheets into complex shapes through a series of continuous bending processes, this method offers numerous advantages, making it a popular choice among manufacturers in various sectors.

Understanding Roll Forming

Roll forming is a process that involves feeding a long strip of metal, typically steel, through a series of rolls that progressively shape it into a desired cross-sectional profile. Unlike traditional methods such as stamping or cutting, roll forming allows for the production of long lengths of material with consistent cross-sections. This continuous method minimizes waste and maximizes efficiency, catering to projects requiring large volumes of a specific design.

Benefits of Custom Roll Forming Steel

1. Design Flexibility One of the primary reasons businesses opt for custom roll forming is the design flexibility it offers. Manufacturers can create intricate shapes and profiles tailored specifically to their needs without the limitations posed by other fabrication methods. Whether it’s for construction, automotive, or consumer goods, roll forming can accommodate various specifications and unique designs.

2. Cost-Effectiveness Custom roll forming can be a cost-effective solution for high-volume production runs. The process minimizes material waste by utilizing the entire strip of steel, and the ability to produce long lengths reduces the number of joints needed, saving both time and labor costs. Additionally, once the initial tooling is established, the incremental cost for additional units remains low, increasing economic efficiency.

custom roll forming steel

3. High Precision and Consistency With custom roll forming, precision is paramount. The machinery used in this process allows for tight tolerances and consistent profiles throughout the production run. This high level of accuracy ensures that each piece fits seamlessly with others, leading to improved assembly times and overall product quality.

4. Material Versatility While steel is the most commonly used material in roll forming, this method can also be employed with a variety of metals, including aluminum and stainless steel. This versatility enables manufacturers to select the best material for their specific application, considering factors like weight, strength, and corrosion resistance.

5. Rapid Production The efficiency of the roll forming process means that manufacturers can scale up production quickly without compromising quality. Custom tooling can be designed to expedite the production of specific profiles, making it ideal for companies with tight timelines or fluctuating demands.

Applications of Custom Roll Forming Steel

The applications of custom roll forming steel are vast and varied. In the construction industry, it is commonly used to produce components such as gutters, metal studs, and roofing systems. The automotive sector harnesses roll formed parts for structural components, chassis, and trim. Additionally, consumer products like industrial shelving, staircases, and furniture benefit from the reliable strength and aesthetic appeal of roll-formed parts.

Conclusion

As industries continue to innovate and demand higher levels of customization, custom roll forming steel stands out as an indispensable tool in modern manufacturing. Its ability to deliver intricate designs, excellent precision, and efficient production makes it a preferred choice for businesses looking to enhance their product offerings. Whether in construction, automotive, or various consumer goods applications, custom roll forming steel paves the way for a sustainable and effective approach to meeting contemporary manufacturing demands.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025