Jan . 09, 2025 12:17

Back to list

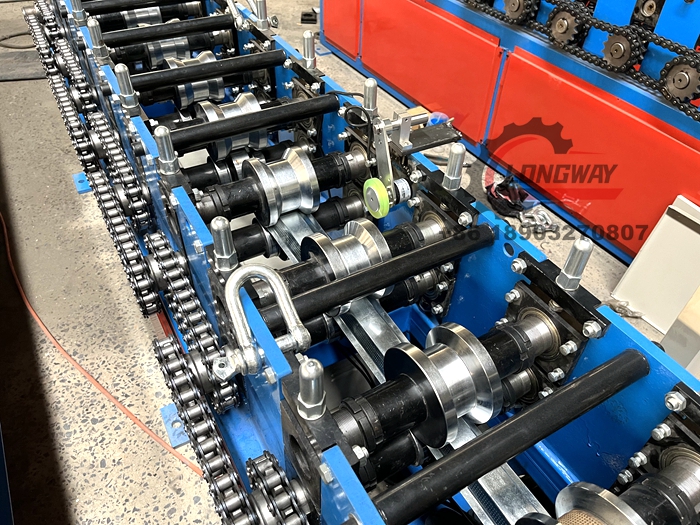

cladding roll forming machine

Exploring the world of custom roll forming machines reveals significant insights into their transformative role in modern manufacturing processes. These machines are pivotal in producing precise, high-quality metal components and offer a perfect blend of engineering excellence and industry-specific expertise.

From a professional perspective, the expertise required to operate and maintain custom roll forming machinery is significant. Engineers and technicians involved in roll forming must possess a deep understanding of material properties, machine dynamics, and tooling design. Continuous professional development ensures that these experts stay abreast of technological advances and innovations in roll forming techniques. The reputation of a manufacturer using custom roll forming machines is often closely tied to their ability to innovate and deliver high-quality products consistently. This reliability builds trust with clients and end-users, affirming the manufacturer's authority and credibility in the industry. Clients seeking roll forming services can maximize the potential of their projects by choosing partners with proven expertise and a track record of successful, custom solutions. Trust in a manufacturer's capabilities is further reinforced by certifications and compliance with industry standards. Quality assurance processes, such as ISO certifications, demonstrate a manufacturer's commitment to maintaining high-quality standards and operational excellence. These credentials assure clients that their projects will be handled with the utmost precision and care, from concept to completion. Investments in advanced technologies, such as computer-aided design and precision engineering, underline the authoritative position of manufacturers in this sector. As industry leaders, they leverage these technologies to push the boundaries of what is possible in roll forming, exploring new applications and markets for their custom machinery. In conclusion, the landscape of custom roll forming machines is characterized by precision, expertise, and innovation. Manufacturers utilizing these machines demonstrate their capability to deliver bespoke solutions that meet the diverse and demanding needs of various industries. By placing a premium on professional knowledge, operational reliability, and technological advancement, these manufacturers establish themselves as trustworthy partners, enabling their clients to achieve competitive advantages through bespoke manufacturing solutions.

From a professional perspective, the expertise required to operate and maintain custom roll forming machinery is significant. Engineers and technicians involved in roll forming must possess a deep understanding of material properties, machine dynamics, and tooling design. Continuous professional development ensures that these experts stay abreast of technological advances and innovations in roll forming techniques. The reputation of a manufacturer using custom roll forming machines is often closely tied to their ability to innovate and deliver high-quality products consistently. This reliability builds trust with clients and end-users, affirming the manufacturer's authority and credibility in the industry. Clients seeking roll forming services can maximize the potential of their projects by choosing partners with proven expertise and a track record of successful, custom solutions. Trust in a manufacturer's capabilities is further reinforced by certifications and compliance with industry standards. Quality assurance processes, such as ISO certifications, demonstrate a manufacturer's commitment to maintaining high-quality standards and operational excellence. These credentials assure clients that their projects will be handled with the utmost precision and care, from concept to completion. Investments in advanced technologies, such as computer-aided design and precision engineering, underline the authoritative position of manufacturers in this sector. As industry leaders, they leverage these technologies to push the boundaries of what is possible in roll forming, exploring new applications and markets for their custom machinery. In conclusion, the landscape of custom roll forming machines is characterized by precision, expertise, and innovation. Manufacturers utilizing these machines demonstrate their capability to deliver bespoke solutions that meet the diverse and demanding needs of various industries. By placing a premium on professional knowledge, operational reliability, and technological advancement, these manufacturers establish themselves as trustworthy partners, enabling their clients to achieve competitive advantages through bespoke manufacturing solutions.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products