Top Custom Roll Forming Machine Manufacturers for Your Production Needs

Custom Roll Former Manufacturers Enhancing Efficiency and Precision in Metal Forming

In today’s manufacturing landscape, the demand for custom metal components has surged, compelling industries to seek specialized solutions that meet their unique production needs. At the forefront of this evolution are custom roll former manufacturers, whose expertise in creating tailored roll forming machines is crucial in an era that advocates for efficiency and precision.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of metal is uniformly transformed into a desired cross-sectional profile. This manufacturing process is favored for producing large quantities of components with high precision and minimal waste. Roll formed products are ubiquitous across various industries, including construction, automotive, and electronics, where they are utilized for structural supports, decorative elements, and more.

The Rise of Customization

Each industry has unique requirements that off-the-shelf solutions may not adequately satisfy. For instance, the construction industry frequently demands specific profiles for roofing and framing applications, while the automotive sector seeks complex shapes for various vehicle components. This is where custom roll former manufacturers play a significant role.

By offering customized solutions, these manufacturers provide tailored machinery that can create complex shapes and profiles that are not only efficient but also cost-effective. Custom roll forming lines can be designed to accommodate different materials, thicknesses, and production speeds, ensuring that the resulting products meet stringent industry standards.

Selection Factors for Custom Roll Former Manufacturers

When selecting a custom roll former manufacturer, there are several factors to consider

1. Experience and Expertise An established manufacturer with years of experience in roll forming can offer valuable insights into the best practices and innovative solutions tailored to your needs.

2. Technology and Equipment The latest advancements in roll forming technology can enhance precision and efficiency. It is crucial to select a manufacturer that employs modern equipment and techniques such as advanced CNC controls and automation.

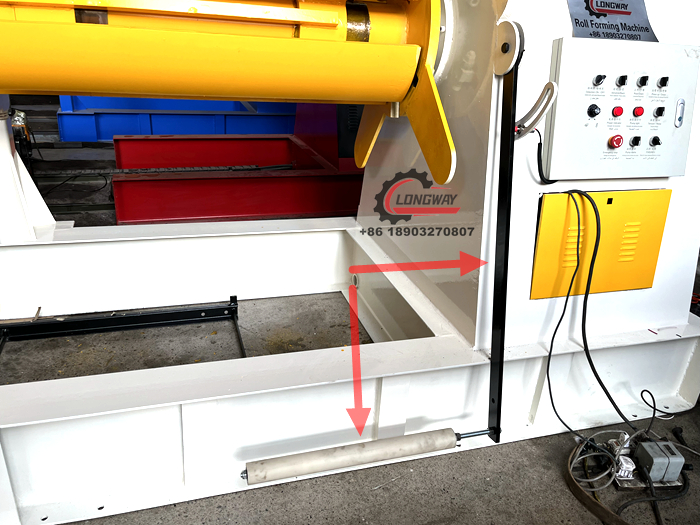

custom roll former manufacturers

4. Quality Assurance A manufacturer with robust quality control processes will ensure that each product meets the necessary specifications. Certifications and adherence to industry standards can be a sign of a reputable manufacturer.

5. Customer Support and Service Post-installation support is vital. A manufacturer that offers excellent customer service and technical support can help troubleshoot issues, ensuring minimal downtime in production.

The Benefits of Working with Custom Roll Former Manufacturers

Engaging with custom roll former manufacturers offers several advantages

- Increased Efficiency By utilizing specialized machinery designed for specific products, manufacturers can optimize their production processes, reducing lead times and lowering costs.

- Enhanced Product Quality Custom roll forming ensures that components are produced to precise specifications, leading to a higher quality end product with fewer defects.

- Flexibility Custom solutions allow businesses to adapt quickly to changing market demands or project requirements, giving them a competitive edge.

- Sustainability Custom roll forming can result in less material waste compared to traditional manufacturing processes, aligning with modern sustainability goals.

Conclusion

As industries continue to evolve, the role of custom roll former manufacturers will become increasingly significant. By investing in specialized roll forming solutions, businesses can achieve higher efficiency and product quality, paving the way for innovation and growth in their respective sectors. The commitment to customization not only meets individual needs but also drives the future of manufacturing towards greater precision and sustainability. Whether in construction, automotive, or other fields, the right partnership with a custom roll former manufacturer can lead to success in an ever-competitive marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025