custom roll former manufacturers

Exploring Custom Roll Former Manufacturers An In-Depth Look

In today's fast-paced manufacturing landscape, the demand for precision-engineered components is ever-increasing. Custom roll forming is one of the most efficient methods for producing a wide array of metal profiles and shapes tailored to specific applications. However, the success of this process largely depends on the expertise and capabilities of custom roll former manufacturers. This article delves into the intricacies of custom roll forming and highlights key considerations when selecting a manufacturer.

Understanding Custom Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is passed through consecutive pairs of rolls. The rolls gradually shape the material into desired profiles. Custom roll forming goes a step further by providing tailored solutions that meet specific design requirements. This process is highly versatile, allowing manufacturers to create complex shapes that may not be achievable through traditional metal fabrication techniques.

The applications of custom roll formed products are vast and varied, encompassing industries like construction, automotive, HVAC, and electronics. From structural framing and roofing panels to brackets and supports, the role of custom roll forming in manufacturing is indeed significant.

Key Considerations When Choosing a Custom Roll Former Manufacturer

1. Experience and Expertise One of the most critical factors in selecting a manufacturer is their experience in the industry. A manufacturer with a proven track record will have the knowledge and skills necessary to produce high-quality products.

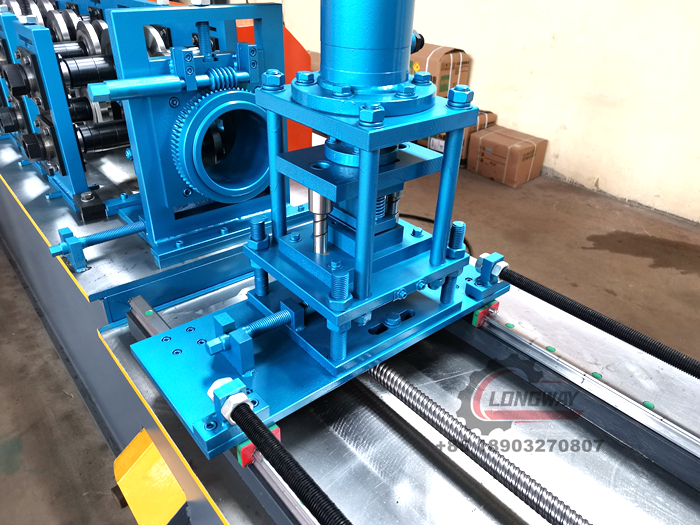

2. Capabilities and Equipment The best custom roll former manufacturers utilize advanced technology and state-of-the-art machinery. This includes everything from CNC machines to precision die design. Assessing their equipment and capabilities can provide insight into the quality of the products they can produce.

custom roll former manufacturers

3. Design and Engineering Support Not all manufacturers offer the same level of design and engineering support. A strong partnership with an experienced manufacturer can help streamline the design process, ensuring that your product specifications are met effectively. The ability to offer suggestions for optimizing the design can also lead to cost savings and better performance.

4. Material Selection Different projects require different materials. Evaluate the range of materials a manufacturer can work with, such as aluminum, steel, or specialized alloys. A versatile manufacturer will be able to accommodate diverse requirements, making them a valuable partner.

5. Customization and Flexibility Look for manufacturers that are open to customization and can handle small or large production runs. Flexibility in production quantities can be especially beneficial for companies that may need to adjust their orders based on market demand.

6. Quality Assurance Adhering to high-quality standards is essential in the manufacturing process. Inquire about the manufacturer’s quality control processes. Certifications and accreditations ensure that they meet industry standards and can deliver consistent, reliable products.

7. Lead Times and Delivery Efficient lead times are crucial in maintaining the competitiveness of your supply chain. A reputable manufacturer should be able to provide clear timelines for production and delivery, ensuring that your projects stay on schedule.

8. Cost-Effectiveness While cost should not be the only consideration, it is important to evaluate pricing structures. A cheaper price does not always equate to a better deal, especially if it compromises quality. A good manufacturer will provide a fair pricing strategy while ensuring the best quality.

Conclusion

Choosing the right custom roll former manufacturer is a vital step in ensuring the success of your project. From their experience and capabilities to their quality assurance practices, each aspect plays a significant role in determining the overall quality and suitability of your custom roll formed products. By carefully evaluating potential manufacturers against these key criteria, you can forge a partnership that not only meets but exceeds your expectations, driving efficiency and success in your operations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025