custom roll former machine

The Custom Roll Former Machine Revolutionizing the Metal Fabrication Industry

In the modern landscape of manufacturing, efficiency and precision are paramount. One machine that has gained prominence in the metal fabrication industry is the custom roll former machine. This innovative piece of equipment allows manufacturers to create complex shapes and profiles from metal sheets with remarkable accuracy and speed.

What is a Custom Roll Former Machine?

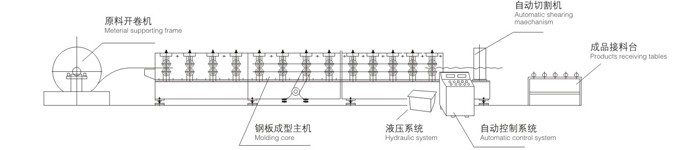

A custom roll former machine is designed to convert flat metal sheets into various shapes and sizes through a process known as roll forming. This process involves feeding a continuous strip of metal through a series of carefully arranged rollers, each of which gradually changes the shape of the metal strip until the desired profile is achieved. The versatility of the custom roll former machine makes it an essential tool for producing products ranging from roofing panels and metal studs to railings and structural components.

Advantages of Custom Roll Formers

One of the key advantages of custom roll former machines is their ability to produce consistent and high-quality products. The precision of the rollers ensures that each piece has the same dimensions, minimizing waste and reducing the need for extensive finishing processes. This consistency is particularly valuable for industries that require large quantities of identical components.

Another significant benefit is the efficiency of the roll forming process. Traditional methods of metal fabrication, such as cutting and welding, can be time-consuming and labor-intensive. In contrast, roll forming allows for high-speed production, enabling manufacturers to meet tight deadlines and high-volume demands. Moreover, since the process involves minimal handling of the material, there is a reduced risk of material damage, leading to cost savings.

custom roll former machine

Customization and Flexibility

One of the standout features of custom roll former machines is their ability to accommodate a wide range of specifications. Manufacturers can tailor the machine to create specific profiles that meet their clients’ unique requirements. This level of customization is essential in today’s competitive market, where the ability to offer bespoke solutions can set a business apart from its competitors.

Additionally, modern roll forming machines can be equipped with advanced control systems, allowing for quick changeovers between different profiles. This flexibility is crucial for companies that operate in industries with varying demands or that deal with multiple clients requiring different products.

Applications Across Industries

Custom roll former machines are utilized across various sectors, including construction, automotive, and appliances. In the construction industry, they play a vital role in producing roofing panels and framing materials, while in the automotive sector, they are used to create structural components and supports. The appliance industry also benefits from custom roll forming when manufacturing enclosures and brackets.

Conclusion

As manufacturing continues to evolve, the need for efficient, precise, and customizable production methods becomes ever more critical. The custom roll former machine stands out as a solution that meets these needs, offering manufacturers the ability to produce high-quality metal components quickly and cost-effectively. Its versatility and efficiency make it an invaluable asset in the metal fabrication industry, enabling businesses to thrive in a competitive marketplace. Investing in a custom roll former machine can ultimately lead to improved productivity, reduced costs, and enhanced customer satisfaction, making it a wise choice for manufacturers looking to the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025