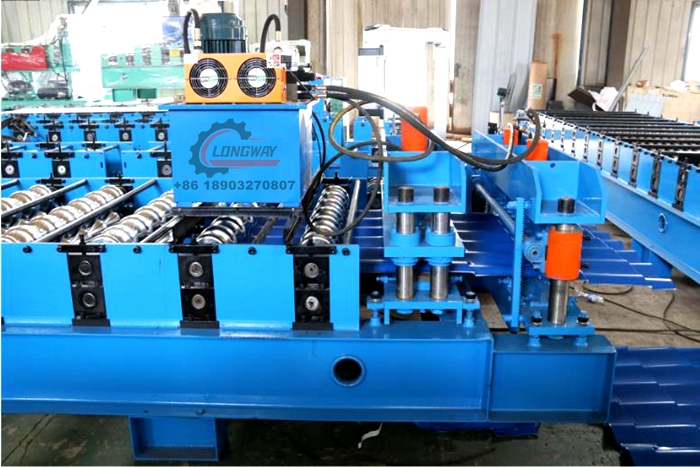

custom roller shutter roll forming machine

The Importance of Custom Roller Shutter Roll Forming Machines

In today’s dynamic manufacturing landscape, businesses continuously seek innovative solutions to enhance efficiency, reduce costs, and provide tailored products to meet specific customer needs. One area where these needs manifest significantly is in the production of roller shutters. Custom roller shutter roll forming machines have emerged as essential equipment in this regard, allowing manufacturers to create high-quality, custom-designed roller shutters that cater to a variety of applications.

Understanding Roll Forming Technology

Roll forming is a process of shaping metal into specific profiles by passing it through a series of rollers. This method is particularly advantageous for producing long lengths of material with uniform cross-sections. The roll forming machines employed in this process are designed to handle different materials, including galvanized steel, aluminum, and PVC, showcasing versatility in manufacturing capabilities.

A custom roller shutter roll forming machine is designed to offer unique specifications to suit the requirements of individual projects. This customization can vary from the dimensions of the shutters to the type of materials being used. This adaptability allows manufacturers to respond swiftly to market changes and customer preferences, thereby gaining a competitive edge.

Key Features of Custom Roller Shutter Roll Forming Machines

Custom roller shutter roll forming machines come equipped with several features that enhance their efficiency and usability

1. Adjustable Rollers These machines often feature adjustable rollers that facilitate the production of various shutter profiles without the need for significant downtime. This capability allows manufacturers to switch between different designs quickly.

2. Automated Systems Many modern roll forming machines integrate automation technology that streamlines the production process. This includes automated material feeding, cutting to length, and stacking, all of which minimize labor costs and reduce the likelihood of human error.

3. Robust Construction Given the demands placed on these machines, they are built to endure rigorous usage over prolonged periods. High-quality materials and engineering ensure reliability and longevity, thus providing excellent return on investment.

custom roller shutter roll forming machine

4. Precision Manufacturing Precision is crucial in the production of roller shutters, as these components must fit seamlessly into various installations. Custom machines are designed to provide high levels of accuracy, ensuring that the finished products meet stringent specifications.

Benefits of Using Custom Roller Shutter Roll Forming Machines

Investing in custom roller shutter roll forming machines yields numerous benefits for manufacturers

- Increased Production Capacity With the ability to produce a wide range of shutter profiles and the automation features of modern machines, businesses can significantly increase their production capacity to meet rising demand.

- Cost-Effectiveness By optimizing the utilization of raw materials and reducing waste during the manufacturing process, companies can lower production costs. Furthermore, custom machines can eliminate the need for additional processes, resulting in substantial savings.

- Customization and Flexibility The ability to produce custom designs gives manufacturers an edge over competitors who may only offer standard sizes and styles. This flexibility allows for catering to niche markets and specific customer preferences.

- Enhanced Quality Control Custom machinery often includes integrated quality control systems that monitor production in real-time. This feature ensures that any deviations from specified standards are caught early, maintaining a high level of product quality.

Conclusion

In conclusion, custom roller shutter roll forming machines represent a significant advancement in manufacturing technology. By providing tailored solutions that meet specific requirements, these machines enhance efficiency, reduce costs, and improve product quality. As businesses seek to remain competitive in an ever-evolving market, the adoption of custom roller shutter roll forming machines will undoubtedly play a critical role in their success. Manufacturers looking to innovate and expand their capabilities should consider investing in such technology to meet the growing demand for custom roller shutters in various applications.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025