custom roller former

Exploring Custom Roller Formers Transforming Metal into Precision Components

In the realm of metal fabrication, custom roller formers play a pivotal role in producing specialized profiles and components that meet the unique requirements of various industries. These machines, often referred to as roll forming machines, utilize a continuous bending process to transform flat metal sheets or strips into desired shapes with high precision and consistency. This article delves into the significance, application, and benefits of custom roller formers in modern manufacturing.

What is a Custom Roller Former?

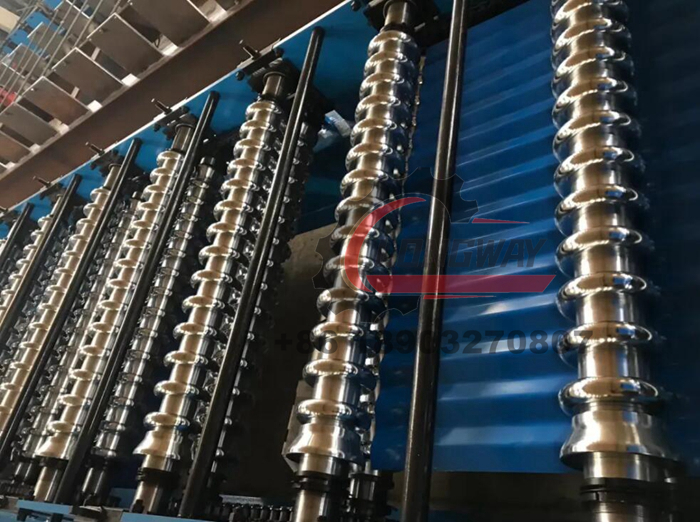

A custom roller former is a specialized machine designed to bend and shape metal into a continuous profile. It consists of a series of rollers, each meticulously crafted to create specific angles and dimensions as the metal moves through the machine. By making use of this process, manufacturers can produce a variety of shapes, including channels, angles, and complex profiles, which are often required in their respective applications.

Applications of Custom Roller Formers

Custom roller formers are utilized across numerous industries, reflecting their versatility and adaptability. Some of the most common applications include

1. Construction Industry Custom roller formers are essential for creating building components such as steel studs, tracks, and roofing materials. These products require precise dimensions to ensure structural integrity and ease of assembly.

2. Automotive Manufacturing The automotive sector employs roller formers to produce parts like frame rails, brackets, and body panels. The ability to create lightweight yet robust components is crucial for fuel efficiency and safety in modern vehicles.

3. Furniture Production In the furniture industry, custom roller formers help produce metal components that are used in a variety of furniture designs. This allows designers to implement innovative features and aesthetics into their products while ensuring durability.

4. HVAC Systems Custom profiles created by roller formers are vital in the heating, ventilation, and air conditioning (HVAC) sector. Ductwork, frames, and support structures often rely on precisely formed metal parts for optimal performance and energy efficiency.

custom roller former

5. Signage and Display Custom roller formers can create unique signage frameworks and display materials. The capability to produce intricate designs allows businesses to stand out with tailored marketing solutions.

Advantages of Custom Roller Formers

Investing in custom roller formers brings several advantages to manufacturers, enhancing productivity and overall product quality

1. High Precision Custom roller formers can produce intricate shapes with minimal tolerances, ensuring that each component meets stringent specifications.

2. Cost Efficiency Although the initial investment may be significant, the long-term savings from reduced material waste and increased production speed can lead to substantial cost reductions.

3. Flexibility These machines can be tailored to produce various profiles, allowing manufacturers to quickly adapt to changing market demands or customer specifications.

4. Consistency The continuous nature of the roll forming process ensures that components are produced uniformly, leading to improved quality control and reduced scrap rates.

5. Scalability Custom roller formers can be employed for both small-batch production and large-scale manufacturing runs, making them a versatile addition to any production line.

Conclusion

The ever-evolving landscape of manufacturing demands innovative solutions that meet specific industry needs. Custom roller formers stand out as a crucial technology, enabling manufacturers to produce high-quality, precision components across diverse applications. As industries continue to push the boundaries of design and functionality, the role of custom roller formers in shaping metal into dynamic products will only grow. Embracing this technology can offer significant competitive advantages, driving efficiency and quality in manufacturing processes.