custom ridge cap roll forming machine

The Innovation of Custom Ridge Cap Roll Forming Machines

The construction and manufacturing industries have seen remarkable advancements with the introduction of specialized machinery, and one of the standout innovations is the custom ridge cap roll forming machine. This essential piece of equipment is designed to fabricate ridge caps for roofing systems, ensuring durability and aesthetic appeal in architectural designs.

Understanding Ridge Caps

Ridge caps are critical components in roofing, serving as protective elements that cover the joints where two sloped roof sections meet. Their primary purpose is to prevent the penetration of water while providing a smooth and finished appearance to the roofline. Properly installed ridge caps can enhance the longevity of a roof and improve its overall functionality. Therefore, investing in high-quality ridge caps is crucial for any building project, whether residential or commercial.

The Role of Roll Forming in Manufacturing Ridge Caps

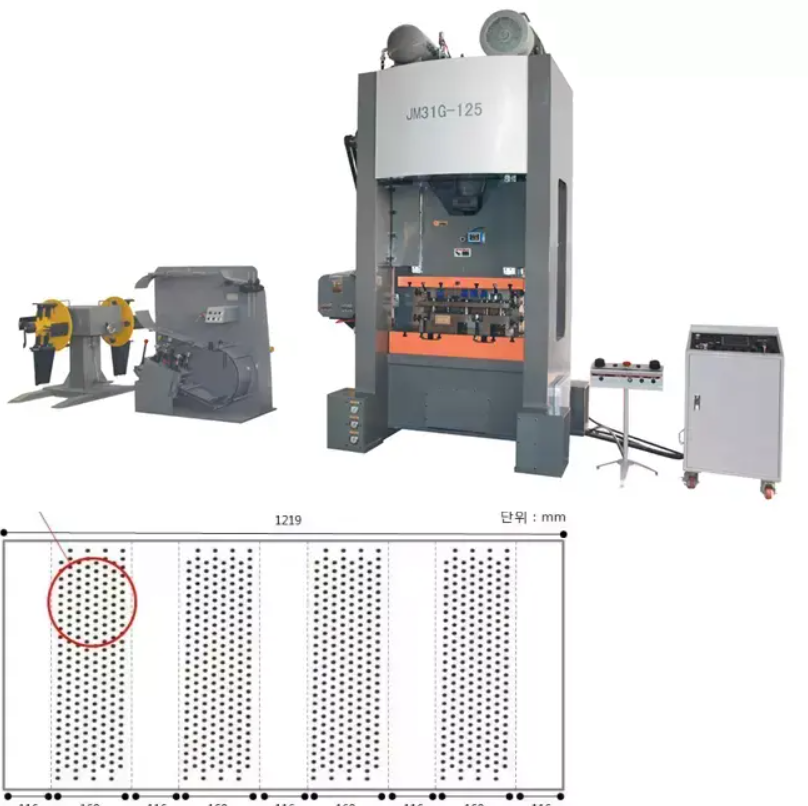

Roll forming is a continuous bending operation in which a long strip of sheet metal, typically steel or aluminum, is gradually shaped into desired profiles. This process allows manufacturers to create consistent, high-quality products with minimized waste and reduced production costs. Custom ridge cap roll forming machines leverage this technology to produce ridge caps tailored to specific architectural requirements, ensuring precise dimensions and profiles.

Key Features of Custom Ridge Cap Roll Forming Machines

1. Customization One of the primary advantages of these machines is the ability to create customized profiles based on client specifications. This versatility allows manufacturers to meet unique design requirements, ensuring that every ridge cap is tailored to the project at hand.

custom ridge cap roll forming machine

2. Efficiency Modern roll forming machines are equipped with advanced automation features that enhance production speed and efficiency. This capability ensures that large volumes of ridge caps can be manufactured quickly without compromising on quality.

3. Durability and Quality Control High-quality materials and state-of-the-art engineering are essential for producing durable ridge caps. Custom ridge cap roll forming machines typically emphasize quality control measures, ensuring that each product meets rigorous industry standards.

4. User-Friendly Operation Many of the latest models come with intuitive interfaces, making them easier to operate for workers at various skill levels. This user-friendliness can result in lower training costs and reduced operational errors.

5. Material Versatility These machines can process a variety of materials like steel, aluminum, or other preferred alloys, ensuring that customers have options that suit their aesthetic preferences and functional needs.

The Economic Benefits

Investing in a custom ridge cap roll forming machine can lead to significant economic advantages for manufacturers. By producing ridge caps in-house, companies can reduce reliance on third-party suppliers, minimizing costs associated with purchasing and shipping. Additionally, the ability to quickly adapt to the latest architectural trends and customer demands can give manufacturers a competitive edge in a rapidly evolving market.

Conclusion

Custom ridge cap roll forming machines represent a significant advancement in the building and construction industries, marrying functionality with design. As roofing systems continue to evolve, these machines provide the necessary flexibility and efficiency to meet modern demands. From improving quality control to enhancing production efficiency, the benefits of investing in such technology are clear. With their ability to produce tailored solutions to fit any project, custom ridge cap roll forming machines are set to play a pivotal role in the future of roofing and construction manufacturing. By embracing these innovations, manufacturers can ensure they remain at the forefront of their industry while providing outstanding value to their customers.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025