Custom Purlin Roll Forming Machine for Versatile Steel Construction Solutions

Custom Purlin Roll Former An Essential Tool in Modern Construction

In the modern construction landscape, efficiency, precision, and customization are paramount. One of the key innovations that have revolutionized the way structural components are manufactured is the custom purlin roll former. This specialized piece of equipment is designed to produce purlins—horizontal members in a roof or wall system that support the roof deck or siding—tailored to the specific requirements of various construction projects.

Understanding Purlins

Purlins are structural elements that play a crucial role in the integrity of a building. They provide support for roof panels, distribute loads, and enhance overall stability. In traditional construction, purlins were often made from wood or steel, requiring significant time and labor to fabricate and install. However, the use of roll-formed steel purlins has gained popularity due to their strength, durability, and cost-effectiveness.

The Role of Custom Purlin Roll Formers

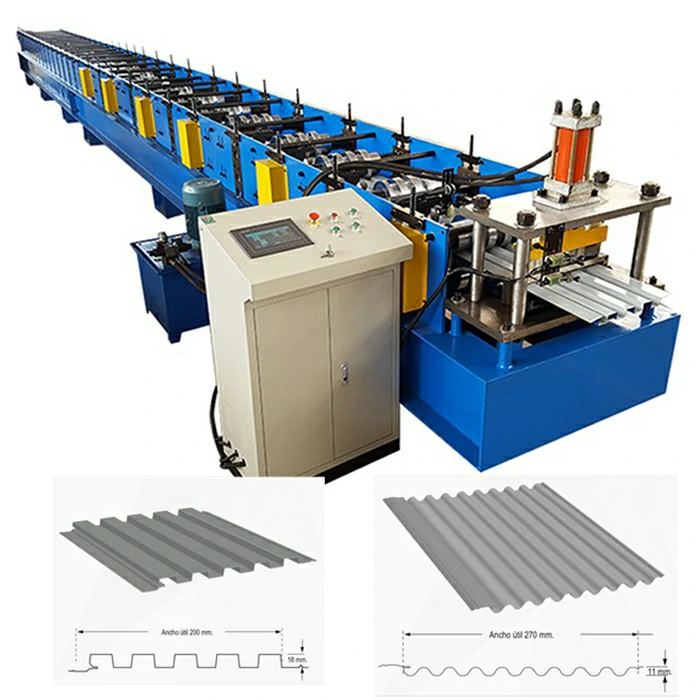

Custom purlin roll formers facilitate the creation of bespoke purlins that meet unique design specifications. These machines take flat metal sheets—typically steel—and process them through a series of rollers that gradually shape the material into the desired profile. This process not only allows for intricate designs but also ensures that each purlin can be produced to precise dimensions, accommodating a wide range of project requirements.

One of the standout features of custom roll formers is their flexibility. They can be adjusted to create various purlin profiles, including C-section, Z-section, and U-section, depending on the structural needs of the building. This is particularly beneficial for contractors and builders who require adaptability in their projects, allowing them to modify their approach based on client specifications or architectural changes.

Advantages of Using Custom Purlin Roll Formers

custom purlin roll former

1. Cost Efficiency Custom purlin roll formers drastically reduce the manufacturing costs associated with producing purlins. Traditional methods often involve extensive labor and lengthy lead times. With a roll former, purlins can be produced quickly and in bulk, effectively reducing waste and labor costs.

2. Enhanced Precision The automated nature of roll forming results in less human error, providing high levels of accuracy in dimensions and profiles. This ensures that each purlin fits perfectly within the larger structure, minimizing the need for adjustments on-site.

3. Material Versatility Roll formers can work with various materials, including galvanized steel and aluminum. This allows builders to choose materials that best suit the requirements of their project, whether that be weight considerations, cost constraints, or environmental factors.

4. Streamlined Production The speed of production with roll formers means that projects can progress more swiftly. Builders can order purlins in advance and have them ready when needed, keeping timelines on track.

5. Reduced Waste The roll forming process generates less scrap material compared to traditional fabrication methods. This is not only good for the environment but also connects to cost savings for construction projects.

Conclusion

In conclusion, the custom purlin roll former has emerged as an invaluable asset in the construction industry, providing a perfect blend of efficiency, precision, and customization. As the demand for innovative building solutions continues to grow, the role of these machines in producing high-quality purlins tailored to specific needs becomes increasingly important. Builders who invest in custom roll forming technology can enhance their productivity, improve their project outcomes, and ultimately provide greater value to their clients. With the relentless evolution of construction techniques and materials, custom purlin roll formers stand at the forefront of this transformation, symbolizing a shift towards more intelligent and efficient building methodologies. Whether you are a contractor, architect, or engineer, understanding and leveraging the capabilities of custom purlin roll formers is essential in navigating the modern construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025