custom purlin making machine

Custom Purlin Making Machine Revolutionizing Steel Fabrication

In the ever-evolving world of construction and manufacturing, efficiency and customization stand out as critical factors for success. One of the technological innovations that embody these principles is the custom purlin making machine. This machine has transformed the traditional processes of steel fabrication, delivering unprecedented levels of precision, speed, and adaptability.

Understanding Purlins

Purlins are horizontal beams that support the roof deck or wall cladding of buildings. They play a crucial role in structural integrity, making them integral components in the construction of warehouses, industrial buildings, and commercial structures. Traditionally, purlins were manufactured through labor-intensive processes that often resulted in inconsistencies. However, the introduction of custom purlin making machines has streamlined this process significantly.

Features of Custom Purlin Making Machines

Custom purlin making machines come equipped with advanced technologies that allow for the production of purlins tailored to specific design requirements. Here are some noteworthy features

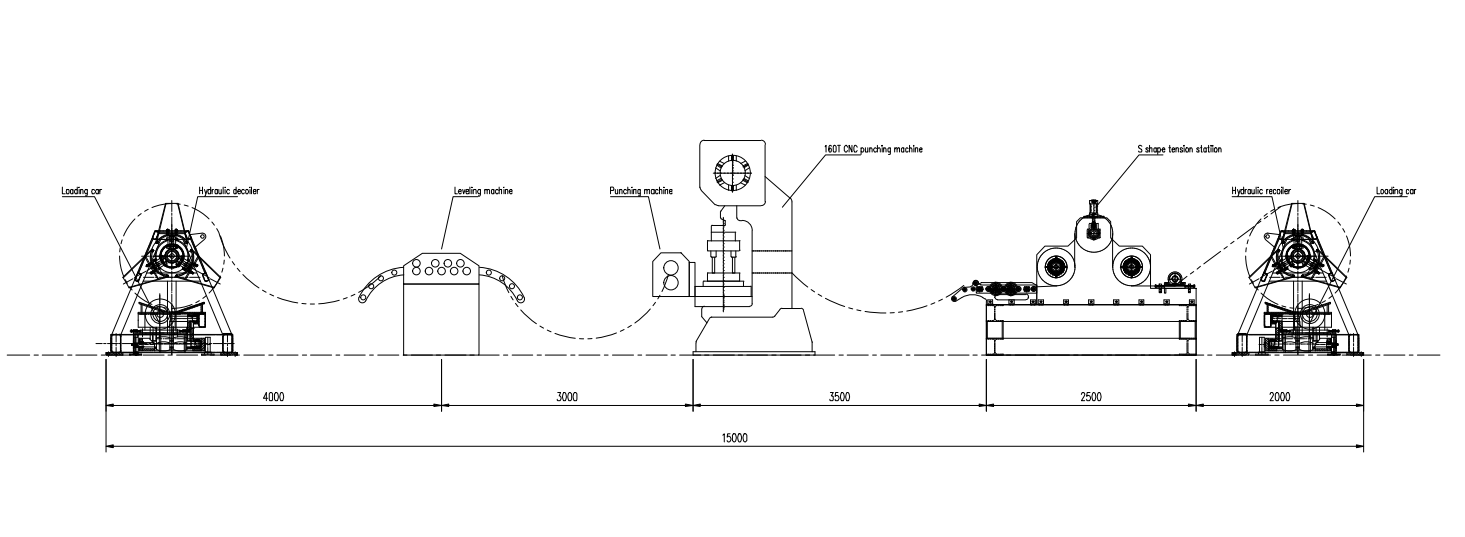

1. Computer Numerical Control (CNC) Modern machines utilize CNC technology, enabling precise control over cutting, shaping, and sizing. This ensures that each purlin produced meets exact specifications, reducing waste and enhancing efficiency.

2. Versatility These machines can be adjusted to fabricate various types of purlins, including C, Z, and U-shaped profiles. This versatility makes them suitable for different construction projects, accommodating diverse design needs.

custom purlin making machine

3. Speed and Efficiency With automated processes, custom purlin making machines can produce purlins at a significantly faster rate than traditional methods. This acceleration not only speeds up the construction timeline but also optimizes labor costs.

4. User-Friendly Interface Many machines feature intuitive controls and interfaces that require minimal training, allowing operators to quickly learn and operate the machinery effectively.

5. Durability and Build Quality Custom purlin making machines are built to withstand the rigors of industrial use, ensuring longevity and reliability. High-quality materials and robust engineering contribute to their resilience.

Economic and Environmental Benefits

Investing in a custom purlin making machine can yield substantial economic benefits. By reducing the need for outsourced fabrication, companies can save on costs while maintaining tighter control over their production schedules. Moreover, the precision of these machines minimizes material waste, contributing to more sustainable manufacturing practices.

Conclusion

In conclusion, the custom purlin making machine represents a significant advancement in the field of steel fabrication. By offering tailored solutions, enhancing efficiency, and promoting sustainability, these machines are not just tools; they are catalysts for innovation within the construction industry. As more companies recognize the advantages these machines bring, we can expect to see a shift towards smarter, more efficient manufacturing processes that meet the evolving demands of modern construction. Embracing this technology is not merely a business choice; it’s a step towards a more sustainable and productive future in the build environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025