Custom Profile Roll Forming Equipment for Precision Metal Fabrication Solutions

Custom Profile Roll Forming Machine A Comprehensive Overview

In the world of manufacturing, efficiency and precision play pivotal roles in the production of various metal components. One of the technologies that has gained immense popularity for its effectiveness is the custom profile roll forming machine. This advanced machinery is designed to create complex profiles from metal sheets, making it an indispensable tool in various industries such as construction, automotive, and appliance manufacturing.

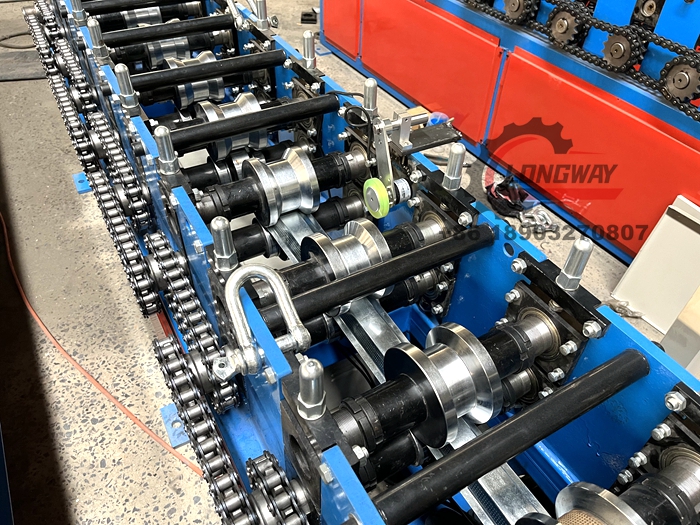

A custom profile roll forming machine operates by continuously feeding a strip of metal, usually steel or aluminum, through a series of rollers. These rollers shape the metal into predefined profiles, which can range from simple shapes to highly intricate designs. Each set of rollers is meticulously engineered to achieve specific contours, ensuring that the final product meets exacting standards.

One of the primary advantages of using a custom profile roll forming machine is its ability to produce high volumes of uniform products with consistent quality

. This is particularly beneficial for industries that require large quantities of specific components, such as roofing systems or structural supports. The machine's automation capabilities reduce the possibility of human error and significantly improve production rates, thereby enhancing overall operational efficiency.custom profile roll forming machine

Moreover, customization is at the heart of the roll forming process. Manufacturers can tailor the machinery to create profiles that meet their specific needs. This flexibility allows businesses to stay competitive by offering unique products that are tailored to their clients' requirements. Whether it’s designing a new architectural element or developing specialized parts for machinery, the ability to customize becomes a significant asset.

In addition to its production capabilities, the custom profile roll forming machine also supports sustainability efforts in manufacturing. By optimizing material usage and minimizing waste during the production process, it promotes environmentally friendly practices. The precise cutting and shaping of materials mean that less scrap is generated, benefiting both the company’s bottom line and the planet.

Maintenance and operation of these machines require specialized knowledge. However, many manufacturers provide comprehensive training programs and support services, ensuring that operators can efficiently use and maintain the equipment. Investing in a custom profile roll forming machine is not only a step towards enhancing production capabilities but also an investment in workforce development.

In conclusion, the custom profile roll forming machine represents a remarkable advancement in manufacturing technology. Its ability to produce high-quality, customized profiles at an efficient pace makes it a crucial asset for various industries. As the demand for specialized metal components continues to grow, the role of roll forming machines will undoubtedly expand, leading to innovations that further enhance production processes and sustainability in manufacturing. For businesses looking to gain a competitive edge, investing in this technology is a strategic move that promises significant rewards.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025