custom precision rollformers

Custom Precision Rollformers A Key to Efficient Metal Fabrication

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency has never been more critical. Among the various techniques that have emerged to meet these needs, custom precision rollformers stand out as a vital technology in metal fabrication. These machines are designed specifically to shape metal into customized profiles while maintaining exceptional levels of accuracy. This article will explore the benefits, applications, and technological advancements associated with custom precision rollformers.

Understanding Rollforming

Rollforming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through a series of rollers that progressively shape it into the desired cross-section. This manufacturing process is particularly beneficial for producing consistent and high-volume parts. Custom precision rollformers enhance this process by allowing manufacturers to tailor their machines and tooling to produce specific shapes and sizes that meet unique customer specifications. This flexibility is crucial in industries where standard solutions do not suffice.

Benefits of Custom Precision Rollformers

1. Enhanced Precision The most significant advantage of custom rollformers is their ability to produce metal parts with high precision. By utilizing advanced computer numerical control (CNC) technology, these machines can achieve tight tolerances, making them ideal for applications that require exact specifications.

2. Cost Efficiency Although the initial investment in custom rollformers can be considerable, they offer long-term savings. The high production speeds and reduced material waste inherent in the rollforming process contribute to lowered manufacturing costs. Custom designs can also minimize secondary operations, further enhancing cost-efficiency.

3. Versatility Custom precision rollformers are versatile enough to handle a wide variety of materials, including different grades of steel, aluminum, and even plastic composites. This adaptability allows manufacturers to meet the diverse needs of various industries, such as construction, automotive, and electronics.

4. Reduced Lead Times With the ability to streamline production processes, custom rollformers can significantly lower lead times. Manufacturers can quickly produce specific parts on demand, thereby responding faster to market fluctuations and customer needs.

custom precision rollformers

5. Sustainability The capability to produce precisely shaped parts with minimal waste makes custom precision rollformers a more sustainable option compared to traditional methods. As manufacturers strive to reduce their environmental footprint, adopting such technologies contributes to greener production practices.

Applications Across Industries

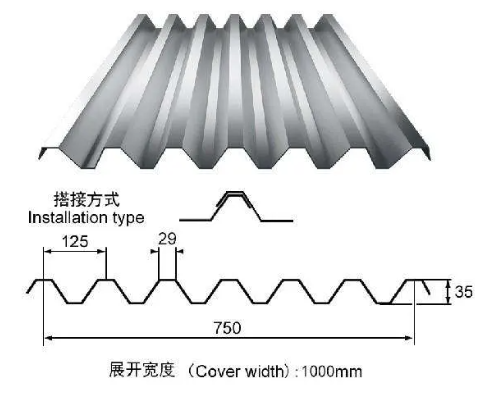

The applications of custom precision rollformers are vast. In the construction industry, for instance, they are used to create structural components, such as steel studs, tracks, and roof panels, all of which require precise dimensions for structural integrity and compliance with building codes. In the automotive sector, components like chassis parts and sections for car bodies are routinely produced using custom rollforming techniques to ensure fit and performance.

Additionally, the electronics industry capitalizes on the precision offered by custom rollformers to manufacture components like enclosures, brackets, and heat sinks. The ability to create intricate shapes that accommodate various electronic components is critical in this fast-paced and technology-driven sector.

Technological Advancements

The advent of Industry 4.0 has significantly impacted the rollforming industry, with custom precision rollformers now featuring enhanced automation and smart technology. Real-time monitoring systems can optimize the production process, providing data on machine performance and quality control. This integration of technology not only improves efficiency but also allows for predictive maintenance, reducing downtime and costly repairs.

Moreover, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) software enable engineers to design complex profiles and simulate the rollforming process digitally before actual production begins. This capability ensures that potential issues can be detected and resolved early, leading to a smoother manufacturing process.

Conclusion

Custom precision rollformers represent a cornerstone of efficient metal fabrication in today's manufacturing landscape. Their ability to produce high-precision parts quickly and cost-effectively across a range of industries makes them an essential tool for companies looking to maintain a competitive edge. As technology continues to advance, the potential for custom precision rollformers will only expand, paving the way for even greater innovations in the world of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025