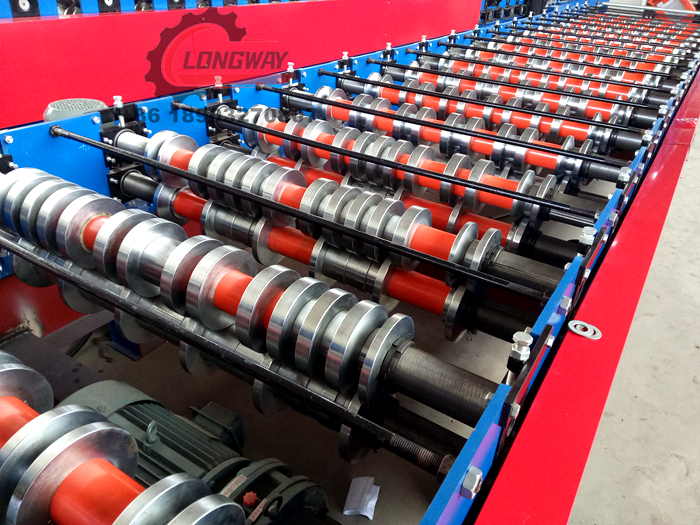

custom pbr roof panel machine

Custom PBR Roof Panel Machine Revolutionizing the Roofing Industry

In today's construction industry, innovation is key to meeting the ever-growing demand for efficient and durable building materials. One of the noteworthy advancements in this realm is the custom PBR roof panel machine. This state-of-the-art technology is specifically designed to manufacture PBR (Pre-painted Galvalume or Galvanized) roof panels, which are renowned for their exceptional durability, aesthetic appeal, and cost-effectiveness.

Understanding PBR Panels

PBR panels are an integral part of modern roofing solutions, particularly in commercial and industrial settings. Their design features a unique profile with a ribbed structure, allowing for quick installation and effective water drainage. Their robustness makes them ideal for various applications, from warehouses and factories to residential buildings. With the addition of custom PBR roof panel machines, manufacturers can produce panels that cater to specific architectural requirements and style preferences.

The Advantages of Customization

The most significant advantage of utilizing a custom PBR roof panel machine is the ability to tailor products to meet specific needs. Not all projects require the same specifications, and customization allows manufacturers to create panels with varying lengths, widths, and profiles. This level of precision ensures that building materials are suitable for unique construction needs, reducing waste and increasing efficiency.

Moreover, customization extends to various finishes and colors. In an era where aesthetics play a vital role in architectural design, the possibility to customize the finish of PBR roof panels helps to match or enhance the overall look of a building. Whether it’s a vibrant color or a subtle matte finish, the ability to offer tailored solutions gives manufacturers a competitive edge in the market.

Efficiency and Production Speed

custom pbr roof panel machine

A pivotal aspect of the custom PBR roof panel machine is its efficiency. Equipped with advanced technology, these machines can produce a high volume of panels in a significantly reduced time frame compared to traditional manufacturing methods. This is particularly advantageous in large-scale construction projects where time is often of the essence. By minimizing lead times, contractors can keep their projects on schedule, which ultimately leads to cost savings.

Additionally, the automation features in modern PBR roof panel machines minimize human error, ensuring that each panel meets the required specifications consistently. This not only enhances the quality of the final product but also streamlines the manufacturing process, allowing businesses to maximize their output.

Sustainability and Eco-Friendliness

As the global focus shifts toward sustainable building practices, the contribution of custom PBR roof panel machines to eco-friendly construction cannot be overlooked. These machines often use materials that are recyclable and designed to last for decades, reducing the need for frequent replacements. Additionally, the manufacturing process typically generates less waste compared to traditional methods, further promoting sustainability in the roofing industry.

By using energy-efficient equipment and practices, manufacturers can further reduce their carbon footprint, making PBR roof panels an environmentally responsible choice. In the long run, both builders and consumers are increasingly aware of their ecological impact, and opting for sustainable materials has become a priority.

Conclusion

The custom PBR roof panel machine represents a significant leap forward in the manufacturing of roofing materials. By combining efficiency, customization, sustainability, and quality, these machines empower manufacturers to meet the varied demands of the modern construction landscape. As the industry continues to evolve, investing in such advanced technologies will likely become a standard practice for those seeking to remain competitive.

In conclusion, the custom PBR roof panel machine is not just a tool; it is a game-changer in the roofing industry. With the ability to produce high-quality, customized panels swiftly and sustainably, it paves the way for innovative building solutions that can adapt to the diverse needs of construction projects. As we look to the future, embracing such technological advancements will undoubtedly lead to more efficient, aesthetic, and sustainable building practices, ultimately reshaping the way we build our environments.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025