Custom-built Roll Forming Machines for Panel Production and Design Solutions

Custom Panel Roll Forming Machine Efficiency and Precision in Manufacturing

In the fast-evolving world of manufacturing, the demand for efficient and precise machinery is ever-increasing. Among the various types of equipment used in this industry, the custom panel roll forming machine has emerged as a vital tool for producing high-quality metal panels and components. These machines enable manufacturers to create a wide range of products, tailored to specific requirements, ensuring flexibility and efficiency in production processes.

A custom panel roll forming machine is designed to transform flat metal sheets into specific shapes and profiles necessary for various applications, including roofing, wall cladding, and other structural components. The process starts with feeding a flat strip of metal, usually steel or aluminum, into the machine. As the metal passes through a series of rollers, it is gradually shaped into the desired profile. This continuous process not only speeds up production but also minimizes waste, making it an environmentally friendly option.

One of the main advantages of using a custom panel roll forming machine is its versatility. Manufacturers can produce panels in various sizes, thicknesses, and shapes, allowing them to meet diverse customer demands. Moreover, by adjusting the roll forming machine's settings, operators can switch between different profiles with minimal downtime, enhancing productivity and responsiveness to market changes.

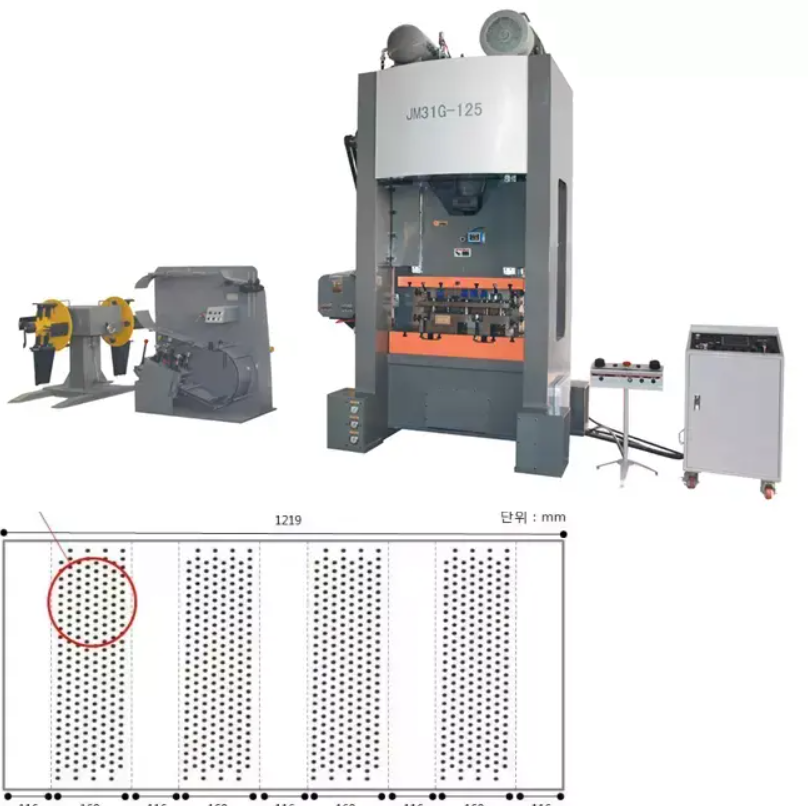

custom panel roll forming machine

Another significant benefit is the precision offered by these machines. The advanced technology used in roll forming allows for tight tolerances, ensuring that each panel produced is consistent in quality and dimension. This level of precision is crucial in applications such as construction, where safety and structural integrity are paramount.

Furthermore, the custom panel roll forming machine can be integrated with other technologies, such as automated cutting and punching systems, to streamline the production process further. This integration not only enhances operational efficiency but also reduces labor costs and minimizes human error, resulting in higher overall quality of the finished products.

In conclusion, the custom panel roll forming machine represents a significant advancement in manufacturing technology. Its ability to produce tailor-made panels with unparalleled efficiency and precision makes it an indispensable asset in various industries. As manufacturers continue to seek innovative solutions to meet the growing demands of their customers, investing in a roll forming machine is a strategic choice that promises to yield substantial returns. By optimizing production capabilities and ensuring high-quality outputs, these machines are set to play a pivotal role in the future of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025