Custom Mobile Roll Forming Equipment for Versatile Metal Fabrication Solutions

Custom Mobile Roll Forming Machine Revolutionizing Metal Fabrication

In the realm of metal fabrication, efficiency, versatility, and precision are paramount. Among the various tools that cater to these needs, the custom mobile roll forming machine stands out as a revolutionary solution. This innovative piece of machinery is designed to streamline the process of shaping metal into desired profiles, which are essential for various applications across multiple industries.

What is a Mobile Roll Forming Machine?

A roll forming machine is a type of industrial equipment used to transform metal sheets into specific shapes through a series of rollers. Traditionally, these machines are stationary, which can limit their usability and the efficiency of operations in larger manufacturing setups. However, a mobile roll forming machine overcomes this limitation by incorporating mobility into the design. This feature enables operators to move the machine to different job sites, making it ideal for on-site construction projects, repairs, and even remote metal fabrication needs.

Customization Meeting Unique Needs

One of the standout features of mobile roll forming machines is their customizability. Different industries have varying requirements for metal shapes, sizes, and specifications. Custom mobile roll forming machines can be tailored to produce a wide range of profiles, from simple angles and channels to complex shapes used in architectural applications. Manufacturers often work closely with clients to develop machinery that meets specific project requirements, ensuring that every roll formed profile adheres to industry standards.

Applications Across Industries

The applications of custom mobile roll forming machines are vast. In construction, these machines are used to produce metal framing components, roofing panels, and siding materials. The ability to produce materials on-site not only saves time and transportation costs but also enhances the speed of project completion.

In the automotive industry, mobile roll forming can be utilized to create components such as brackets, supports, and other structural elements. This flexibility allows manufacturers to adapt quickly to changing production demands, ensuring they remain competitive in a rapidly evolving marketplace.

Furthermore, in the renewable energy sector, particularly solar energy, mobile roll forming machines can be employed to manufacture mounting systems and supports for solar panels. The ability to roll-form steel components on-site allows for greater customization according to the specific requirements of each installation, maximizing efficiency and performance.

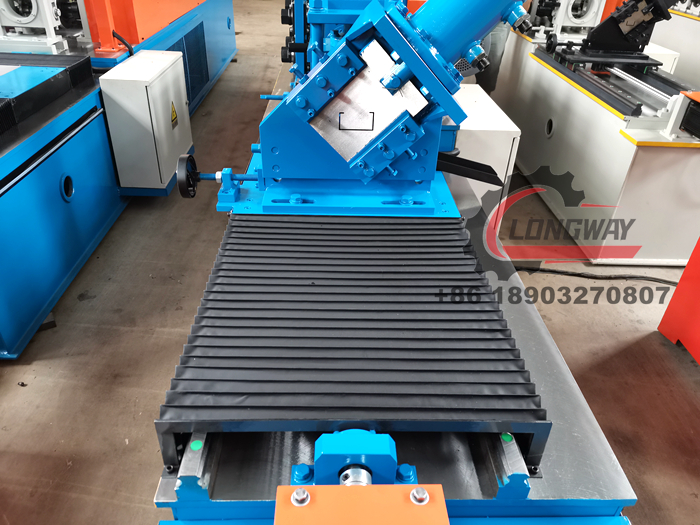

custom mobile roll forming machine

Advantages of Mobile Roll Forming Machines

The chief advantages of using a custom mobile roll forming machine include

1. Portability Being able to transport the machine directly to the job site cuts down on lead times and shipping costs.

2. Efficiency By producing parts on-demand, projects can proceed without waiting for materials to be delivered from a central location.

3. Customization Tailored machinery ensures that manufacturers can meet precise specifications, enhancing product quality and satisfaction.

4. Reduced Waste On-site production minimizes leftover materials and allows for better management of resources, contributing to sustainability efforts.

5. Increased Production Speed With the ability to quickly set up and start producing, projects can move forward without the delays often caused by external suppliers.

Conclusion

The introduction of custom mobile roll forming machines signifies a major advancement in metal fabrication technology. As industries continue to evolve and demand greater efficiency, versatility, and customization, these machines are poised to play an increasingly vital role in both manufacturing and construction sectors. By enabling on-site production capabilities, businesses can enhance their operational flexibility, reduce costs, and improve overall productivity. In essence, custom mobile roll forming machines are not just tools; they symbolize the future of adaptive manufacturing solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025