Custom Metal Stud Fabrication Equipment for Efficient Construction Solutions

Custom Metal Stud Forming Machines Revolutionizing the Construction Industry

In the ever-evolving landscape of construction and manufacturing, the efficiency and precision of tools play a vital role in determining the overall success of projects. One such innovation that has gained significant attention is the custom metal stud forming machine. These machines are specifically designed to fabricate metal studs that are essential components in modern construction, particularly in framing and support applications. With the ability to tailor these machines to the unique needs of different projects, businesses can significantly enhance productivity while ensuring high-quality outputs.

The Importance of Metal Studs

Metal studs are a staple in contemporary construction, providing structural support in walls, ceilings, and other architectural elements. Unlike traditional wood framing, metal studs offer numerous advantages, including resistance to fire, pests, and warping. They are lightweight, durable, and often more cost-effective in the long run. As a result, the demand for properly fabricated metal studs has surged, leading to the increased adoption of specialized machinery to produce them.

Customization for Enhanced Efficiency

The primary advantage of custom metal stud forming machines is their ability to be tailored to specific project requirements. Each construction site may have unique specifications regarding the size, shape, and quantity of metal studs needed. Through the use of advanced technology, manufacturers can design machines that can quickly switch between different profiles and dimensions, accommodating various project needs without significant downtime. This versatility not only streamlines the production process but also minimizes material waste.

Moreover, customized machines can integrate additional features, such as automatic cutting, punching, and bending capabilities. This automation reduces the need for manual labor, decreasing the risk of human error and enhancing overall safety on the job site. Operators can focus on quality control and final assembly, ensuring that the metal studs produced meet stringent industry standards.

Economic and Environmental Benefits

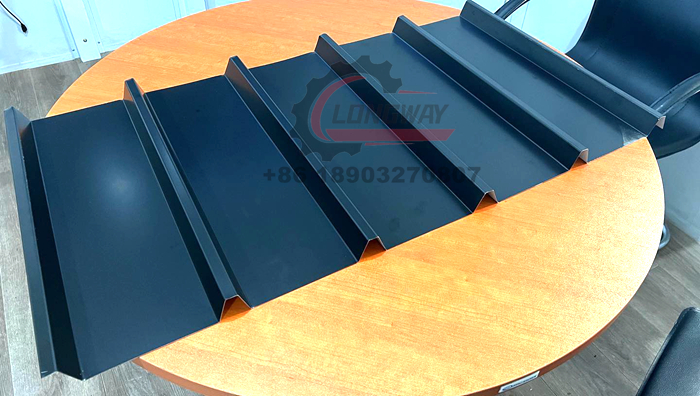

custom metal stud forming machine

Investing in custom metal stud forming machines is not just a matter of improving productivity; it also has economic implications. By producing metal studs in-house, companies can cut costs associated with outsourcing and transportation. Moreover, the speed and efficiency of these machines can result in shorter project timelines, allowing businesses to take on more projects and increase profitability.

From an environmental perspective, these machines play a crucial role in promoting sustainable construction practices. By creating metal studs from recycled materials, the forming process can significantly reduce the ecological footprint associated with construction activities. Additionally, the durability of metal framing contributes to the longevity of structures, decreasing the need for frequent repairs and replacements.

Technological Innovations

The advancements in technology have further enhanced the capabilities of custom metal stud forming machines. With the integration of computer numerical control (CNC) systems, these machines can achieve precise cuts and bends, drastically reducing waste and improving measurement accuracy. Modern software allows for easy design modifications and efficient project management, making the manufacturing process more agile and responsive to changes in client demands.

Furthermore, the advent of Industry 4.0 and the Internet of Things (IoT) has paved the way for smart manufacturing solutions. Custom metal stud forming machines can now collect and analyze data in real-time, providing insights into production efficiency and areas for improvement. This connectivity allows businesses to optimize operations, leading to heightened competitiveness in the market.

Conclusion

Custom metal stud forming machines represent a significant advancement in the construction industry, providing tailored solutions that enhance efficiency, economic viability, and environmental sustainability. As the construction sector continues to grow and evolve, the demand for these innovative machines will likely increase, driving competition and fostering new technologies. By investing in custom solutions, companies not only meet their project requirements more effectively but also position themselves at the forefront of a rapidly advancing industry. As we look to the future, the role of custom metal stud forming machines will undoubtedly become more integral to modern construction practices, facilitating efficient, safe, and sustainable building processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025