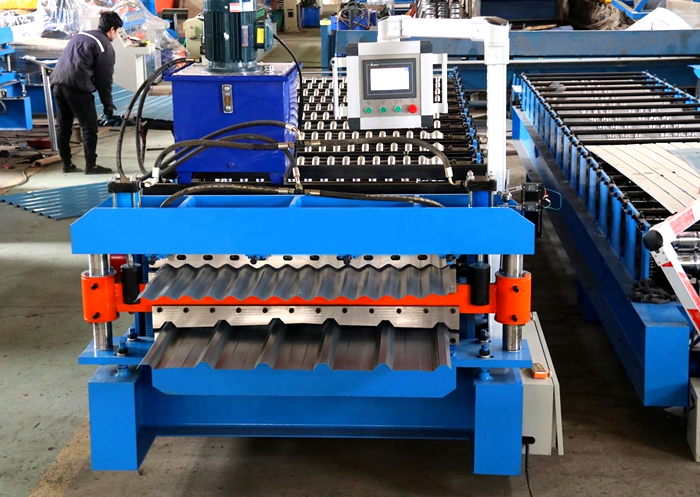

custom metal stud and track roll forming machine

Custom Metal Stud and Track Roll Forming Machine Revolutionizing Construction

In the ever-evolving construction industry, efficiency, durability, and precision are paramount. One of the critical components that aid in achieving these goals is the metal stud and track system. To produce these essential elements, the custom metal stud and track roll forming machine has emerged as a game-changer, revolutionizing how construction materials are manufactured.

What is a Roll Forming Machine?

Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is passed through sequential rollers to gradually shape it into specific profiles. The roll forming machine consists of multiple sets of rollers arranged in a fixed sequence, each gradually bending the metal strip closer to the desired shape. This process is widely used for producing various construction components, including metal studs and tracks.

Importance of Metal Studs and Tracks

Metal studs and tracks form the backbone of modern construction, particularly in commercial and residential buildings. They are preferred over traditional wood framing due to their strength, lightweight nature, fire resistance, and pest deterrence. Metal framing provides superior durability and can support heavier loads, making it ideal for larger structures. Furthermore, they also offer excellent insulation properties, which improve the energy efficiency of buildings.

Benefits of Custom Metal Stud and Track Roll Forming Machines

1. Precision Manufacturing Custom roll forming machines are designed to ensure that each metal stud and track is produced with precision. This accuracy is pivotal in construction, where any deviations can lead to structural issues. The machine can be adjusted to produce varying sizes and shapes, accommodating the specific requirements of a project.

custom metal stud and track roll forming machine

2. Cost Efficiency By automating the manufacturing process, roll forming machines reduce labor costs significantly. They can produce large quantities of metal studs and tracks in a fraction of the time it would take to manufacture them manually. This efficiency not only lowers production costs but also accelerates project timelines.

3. Material Waste Reduction The roll forming process maximizes material usage, minimizing waste. The strips of metal are shaped specifically, allowing for inline adjustments that make the most out of the raw material. This environmentally friendly approach not only saves costs but also aligns with sustainability practices in modern construction.

4. Customization With the ability to tailor designs to meet specific project requirements, custom roll forming machines allow construction companies to achieve unique designs without the limitations often encountered with traditional manufacturing methods. The flexibility to produce different profiles on demand makes them invaluable in meeting the complex needs of contemporary architecture.

5. Increased Strength The cold-formed steel created through the roll forming process tends to be stronger than its hot-rolled counterparts. The controlled manufacturing environment ensures that each stud and track maintains high strength-to-weight ratios, making them suitable for various applications, including load-bearing walls and ceilings.

Applications of Metal Studs and Tracks

Custom metal studs and tracks produced by roll forming machines have numerous applications in the construction industry. They are widely used in interior wall framing, suspended ceilings, exterior framing systems, and shear walls. Additionally, their lightweight nature and resistance to rotting or warping make them ideal for applications in regions with high humidity or temperature variations.

Conclusion

The advent of custom metal stud and track roll forming machines has transformed the construction landscape, offering unparalleled benefits in production speed, cost, and quality. Their precision manufacturing capabilities, coupled with the ability to customize designs, help construction companies meet the demands of modern building projects effectively. As the industry continues to innovate, these machines are likely to play an increasingly vital role in shaping the future of construction materials, ultimately leading to stronger, safer, and more sustainable structures. Whether for new constructions or renovation projects, the roll forming machine's impact is undeniable, solidifying its place as a cornerstone of contemporary construction practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025