Custom Metal Roofing Roll Forming Machine for Efficient Construction Solutions

Custom Metal Roofing Roller Machines Revolutionizing Roofing Solutions

In the ever-evolving construction and roofing industry, the demand for durable and aesthetically pleasing roofing solutions has never been higher. Among the various options available, metal roofing has emerged as a popular choice due to its longevity, energy efficiency, and modern appeal. To meet this growing need, custom metal roofing roller machines have become indispensable tools for manufacturers and contractors alike.

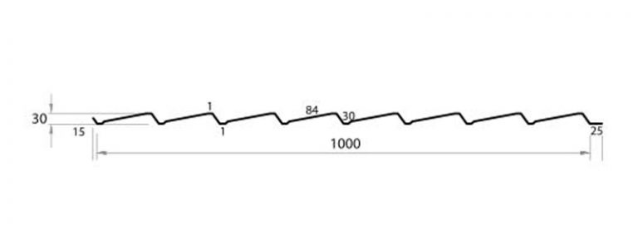

A custom metal roofing roller machine is designed to produce metal roofing panels tailored to specific project requirements. Unlike standard machines, these rollers can be engineered to produce unique profiles, widths, and thicknesses, allowing for a high degree of customization. This flexibility is crucial for contractors who want to offer distinctive roofing solutions that stand out and cater to the varied preferences of their clients.

Benefits of Custom Metal Roofing Roller Machines

1. Precision Engineering One of the standout features of custom roller machines is their ability to manufacture panels with precision. These machines utilize advanced technology that ensures consistent quality, dimensional accuracy, and a flawless finish. This precision reduces waste, saves materials, and ultimately lowers costs for roofing contractors.

custom metal roofing roller machine

2. Versatility Custom metal roofing roller machines are designed to accommodate a variety of materials, including aluminum, steel, and copper. This versatility allows roofing companies to diversify their offerings, making it easier to meet the requirements of different projects and clients. Additionally, the ability to produce various profiles (such as standing seam, corrugated, or flush panels) enhances the machine's utility in a competitive market.

3. Time Efficiency In the fast-paced construction industry, time is of the essence. Custom metal roofing roller machines streamline the manufacturing process by reducing lead times. With the capability to produce roofing panels on-site, contractors can minimize delays and take on more projects, ultimately increasing their profitability.

4. Cost-Effectiveness While the initial investment in a custom roofing roller machine may seem substantial, the long-term savings make it worthwhile. By eliminating the need for outsourcing materials and reducing waste, contractors can significantly decrease overhead costs. Furthermore, the durability of metal roofing panels means that clients are less likely to incur repair or replacement expenses in the near future.

Conclusion

As the demand for metal roofing continues to rise, the importance of custom metal roofing roller machines cannot be overstated. These machines provide manufacturers and contractors with the tools needed to produce high-quality, customizable roofing solutions that meet modern architectural demands. With benefits such as precision engineering, versatility, time efficiency, and cost-effectiveness, investing in a custom metal roofing roller machine is a strategic move for any roofing business aiming to thrive in a competitive landscape. Embracing this technology not only enhances service offerings but also contributes to the overall success and sustainability of roofing operations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025