custom metal roofing panel machine

Custom Metal Roofing Panel Machine Revolutionizing the Roofing Industry

In recent years, the construction and roofing industries have witnessed a significant transformation driven by advancements in technology and manufacturing processes. One of the standout innovations in this realm is the custom metal roofing panel machine. This sophisticated equipment is engineered to produce high-quality metal roofing panels tailored to specific design and application needs, providing both efficiency and flexibility for contractors and builders alike.

Understanding Metal Roofing Panels

Metal roofing panels are a popular choice among builders and homeowners for a variety of reasons. They are durable, weather-resistant, and energy-efficient. Metal roofs can withstand extreme weather conditions, including heavy rain, snow, and high winds, making them ideal for diverse climates. Additionally, metal roofing materials, often made from steel, aluminum, or copper, reflect solar heat, contributing to reduced cooling costs in warm weather.

The Role of Custom Metal Roofing Panel Machines

Traditionally, the production of metal roofing panels required significant time and labor, often resulting in delays and inconsistencies. The introduction of custom metal roofing panel machines has changed this landscape dramatically. These machines are capable of producing various panel profiles, lengths, and widths tailored to the unique specifications of each project. This customization ensures that builders can meet architectural requirements without the hassle of pre-manufactured panels that may not fit perfectly.

Key Features of Custom Metal Roofing Panel Machines

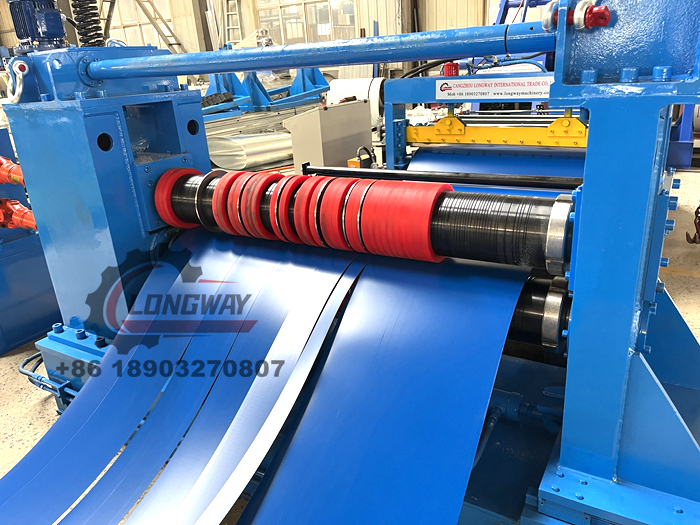

1. Automation and Precision Modern custom metal roofing panel machines are equipped with advanced automation technology that allows for precise cutting, shaping, and forming of metal sheets. Automated controls enhance the accuracy of dimensions, resulting in panels that fit perfectly without requiring additional modifications.

2. Flexibility and Versatility These machines can produce a wide range of panel styles, including standing seam, corrugated, and tile profiles. This flexibility means that contractors can efficiently address different project requirements without needing separate machines for each type of panel.

custom metal roofing panel machine

3. Reduced Waste Custom machines minimize material waste by optimizing the production process. By producing panels on-demand, builders can reduce excess inventory and utilize materials more efficiently, which is not only cost-effective but also environmentally friendly.

4. Speed of Production With the ability to quickly produce high volumes of metal panels, custom machines drastically reduce lead times. This efficiency allows contractors to complete projects faster, ultimately enhancing customer satisfaction.

5. User-Friendly Interface Many of these machines come with intuitive, user-friendly interfaces that simplify operation. Training personnel to use these machines takes less time, and operators can quickly learn how to make adjustments for various panel specifications.

Applications and Benefits

The applications of custom metal roofing panel machines extend beyond residential roofing. They are also extensively used in commercial buildings, agricultural facilities, and industrial structures. The ability to produce custom panels on-site or close to the project location can lead to significant logistical savings, reducing transportation costs and delivery times.

From a financial perspective, investing in a custom metal roofing panel machine can greatly enhance a contractor’s competitive edge. By providing tailored solutions that meet client demands for specific panel designs, contractors can differentiate themselves in a crowded market. The long-term durability and energy efficiency of metal roofs can also be a significant selling point to environmentally conscious consumers.

Conclusion

The custom metal roofing panel machine represents a pivotal advancement in the construction industry. By merging technology with efficient manufacturing, these machines empower contractors to deliver high-quality, customized roofing solutions that meet the demands of modern architecture and design. As the industry continues to evolve, the integration of such advanced machinery is likely to play a crucial role in shaping the future of roofing, ensuring that quality, efficiency, and innovation remain at the forefront. Whether for a residential home or a large-scale commercial project, the custom metal roofing panel machine is positioning itself as an indispensable tool for the successful roofing contractor.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025