High-Quality Custom Metal Roofing Machines Available for Purchase Today

Custom Metal Roofing Machines for Sale Your Guide to Quality and Efficiency

In the contemporary construction industry, the choice of materials plays a critical role in determining the overall quality, durability, and aesthetic appeal of a structure. One such material that has gained immense popularity is metal roofing. With its myriad of advantages, including energy efficiency, longevity, and low maintenance, metal roofing has become a preferred choice for both residential and commercial buildings. However, to harness the full potential of metal roofing, businesses and contractors often seek custom metal roofing machines that can deliver quality products tailored to their specific needs.

The Rise of Metal Roofing

Metal roofing isn’t just a trend; it represents a significant shift in how structures are designed and built. Its resistance to harsh weather conditions, lightweight nature, and minimal maintenance make it an attractive option for building owners and contractors alike. Furthermore, metal roofs can be made from a variety of materials, including steel, aluminum, copper, and zinc, adding versatility to their application. But to capitalize on this market demand, the right machinery is necessary to produce metal roofing panels that meet the required standards.

Benefits of Custom Metal Roofing Machines

Investing in custom metal roofing machines offers numerous advantages, particularly for businesses looking to stay ahead of the competition. Here are some reasons why businesses should consider these machines

1. Tailored Solutions Custom machines can be designed to meet specific production needs, ensuring that the panels produced are of the desired quality, style, and functionality. Whether it’s different sizes, shapes, or finishes, customization allows manufacturers to cater to a diverse market.

2. Increased Efficiency Modern metal roofing machines are equipped with advanced technology that enhances production efficiency. Features such as automated cutting, bending, and rolling processes reduce manual labor, minimize errors, and increase speed, allowing businesses to respond rapidly to customer demands.

3. Cost-Effectiveness While the initial investment in a custom metal roofing machine may seem significant, the long-term savings can be substantial. Reduced labor costs, lower waste production due to precision engineering, and the ability to produce high-quality products efficiently all contribute to enhanced profitability.

4. Quality Control Custom machines allow for better quality control throughout the production process. With the ability to monitor and adjust settings in real time, manufacturers can maintain high standards, ensuring that every panel meets industry specifications and customer expectations.

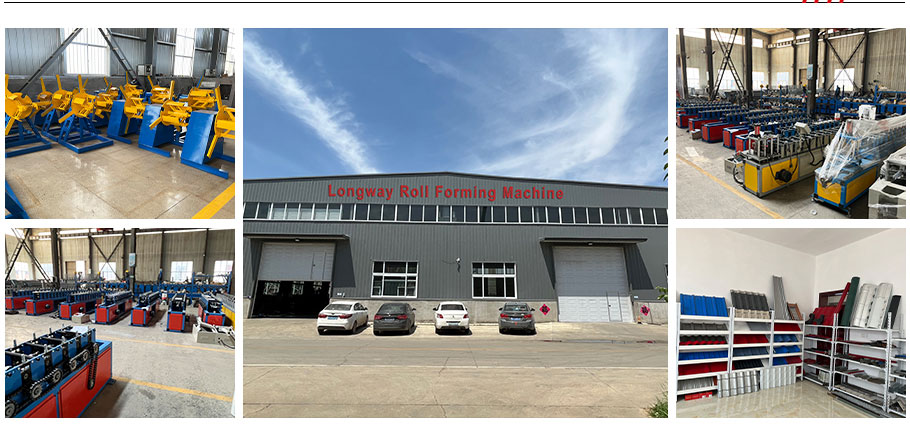

custom metal roofing machine for sale

5. Flexible Design Options The flexibility offered by these machines means that businesses can easily adapt to changing market trends. Unique designs and styles in metal roofing can be produced quickly, giving businesses a competitive edge in the ever-evolving construction market.

Choosing the Right Custom Metal Roofing Machine

When considering the purchase of a custom metal roofing machine, key factors should be assessed

- Production Capacity Evaluate how much production your business anticipates. Make sure the machine can meet your expected output levels. - Specifications and Features Identify the specific features required for your product, such as types of materials the machine can handle, the thickness of the metal, and the range of panel designs it can produce.

- Supplier Reputation Research the manufacturer or supplier of the machine. Look for reviews, case studies, and examples of previous installations to ensure you’re investing in a reputable product.

- Technical Support and Training Ensure that the supplier offers adequate training and support for operating and maintaining the machine. This will help in minimizing downtime and ensuring smooth operations.

- Return on Investment Consider the long-term benefits against the initial costs. Analyze how the machine will contribute to your overall operation and increase profitability.

Conclusion

In conclusion, the demand for custom metal roofing machines is on the rise as the construction industry continues to embrace metal roofing solutions. By investing in high-quality, reliable machinery, businesses can enhance their production capabilities while delivering superior products to their customers. With tailored solutions, increased efficiency, and the potential for significant cost savings, custom metal roofing machines manifest an invaluable asset for any roofing manufacturer or contractor looking to thrive in a competitive market. As you consider expanding your operations, take the time to explore the options available, ensuring you choose a machine that aligns with your goals for quality and efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025