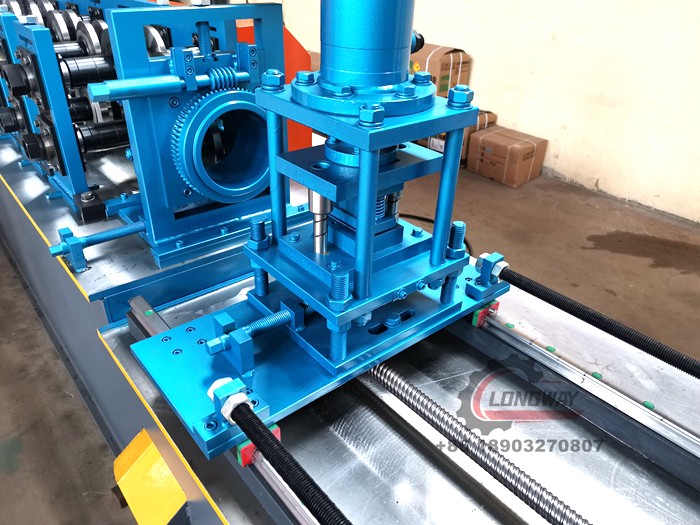

custom metal roll forming machines for sale

Custom Metal Roll Forming Machines for Sale Ultimate Solutions for Efficient Manufacturing

In today’s competitive manufacturing landscape, the demand for precision and efficiency has never been greater. One of the most effective ways to meet these demands is through the use of custom metal roll forming machines. These machines provide unparalleled versatility and are essential for companies seeking to optimize their production processes and improve quality. This article will explore the benefits and features of custom metal roll forming machines available for sale.

Roll forming is a long-established manufacturing process where a continuous strip of metal is fed through a series of rollers that gradually shape it into a desired profile. This process is especially useful for producing metal components with consistent cross-sectional shapes and can create an array of products, from roofing panels to automotive parts. Custom metal roll forming machines cater specifically to the unique needs of different industries, making them an invaluable asset for manufacturers looking to enhance their capabilities.

One of the primary advantages of custom roll forming machines is their adaptability. Manufacturers can specify the design of the rollers, the materials used, and the finishing processes required, allowing for the production of customized components that meet exact specifications. This tailored approach not only ensures that the final products meet quality standards but also allows for quicker turnarounds and reduced waste during the manufacturing process. With the ability to produce shorter production runs economically, custom roll forming machines are ideal for companies looking to create niche products or respond to specific market demands.

custom metal roll forming machines for sale

Moreover, these machines typically boast high efficiency and automation. Advanced custom metal roll forming machines integrate the latest technology to streamline operations. Features such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems enable operators to set parameters easily and monitor the production process in real time. This leads to less downtime, as machines can efficiently transition from one product line to another without the need for extensive manual reconfiguration. Consequently, businesses can increase their output and productivity, ensuring they remain competitive in a fast-paced environment.

When shopping for custom metal roll forming machines for sale, buyers should consider several factors. Firstly, it is important to assess the types of materials the machine can handle. Common materials include aluminum, steel, and various alloys, each requiring different specifications. Additionally, potential buyers should evaluate the machine's forming capacity, speed, and the maximum and minimum profile dimensions it can produce. Understanding these parameters ensures that the machine purchased aligns with the specific production needs of the business.

Another crucial aspect is the manufacturer’s reputation and after-sales service. Investing in custom roll forming machines is a significant financial commitment, so it is essential to choose a reliable supplier that provides robust customer support. Post-purchase service can include installation, training for operators, and ongoing maintenance, all of which contribute to the longevity and efficiency of the machinery.

In conclusion, custom metal roll forming machines are key players in modern manufacturing, offering tailored solutions that enhance efficiency and product quality. With the ability to adapt to specific requirements, these machines are not only versatile but also a critical investment for manufacturers aiming to stay ahead of the competition. When selecting a machine, considering factors such as material compatibility, operational capacity, and supplier support will lead to informed decisions that can greatly benefit production processes. Investing in custom roll forming technology is a step toward greater productivity and success in the ever-evolving manufacturing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025