custom metal roll forming machines for sale

Custom Metal Roll Forming Machines for Sale

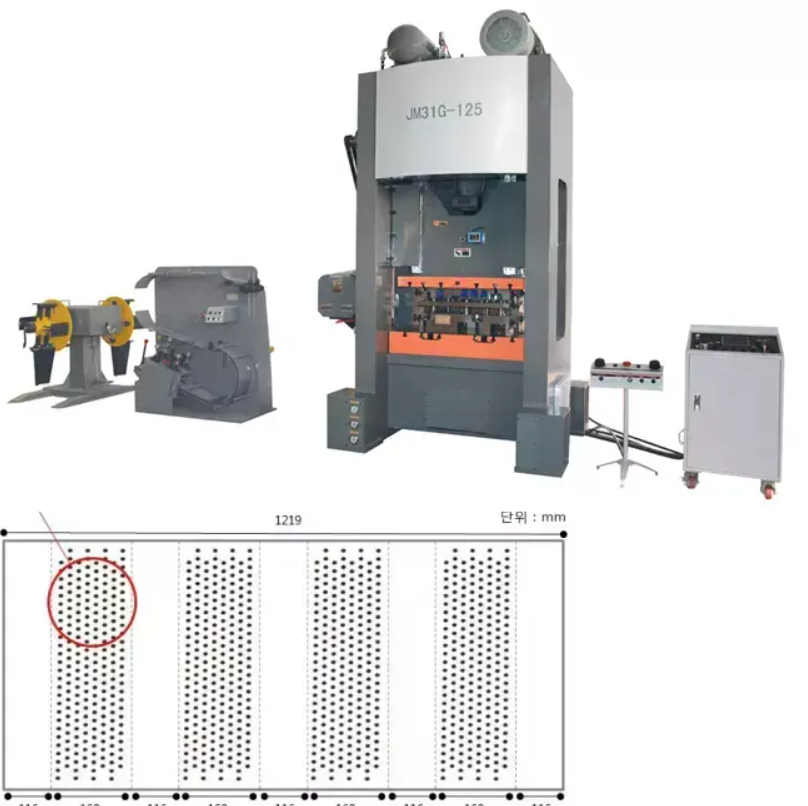

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency has led to the increasing prominence of custom metal roll forming machines. These machines play a critical role in the production of metal components through a process known as roll forming, where sheets or strips of metal are continuously fed through pairs of rolls to create desired shapes. This technology is not only efficient but also cost-effective, making it an attractive choice for manufacturers across various industries.

Understanding Roll Forming

Roll forming is a manufacturing process that transforms flat metal strips into specific shapes using a series of rollers. This process allows manufacturers to produce parts that are uniform in consistency and precision, with minimal waste. The ability to create complex profiles while maintaining tight tolerances has made roll forming a preferred choice for producing items such as roof panels, metal channels, and structural shapes for construction.

The process involves feeding metal strips through a series of rollers that gradually shape the material. Each set of rollers alters the profile slightly until the final desired shape is achieved. Due to its efficiency, the roll forming process is often preferred for high-volume production runs, providing a quick turnaround on projects while ensuring quality.

Why Choose Custom Solutions?

While standard roll forming machines are widely available, custom metal roll forming machines provide a range of advantages for businesses looking to meet specific manufacturing needs. These machines can be tailored to produce unique profiles and shapes that may not be achievable with standard equipment. Custom solutions offer flexibility in design and functionality, allowing manufacturers to innovate and adapt to changing market demands.

1. Tailored Designs Custom machines can be engineered to produce specific profiles and designs that fit particular project requirements. This capability enables manufacturers to differentiate their products in a competitive market.

2. Enhanced Efficiency By designing machines that cater specifically to the production needs of a business, manufacturers can significantly improve their operational efficiency. Custom machines can streamline the production process, minimize downtime, and reduce the need for secondary operations.

custom metal roll forming machines for sale

4. Quality Control Custom machines are often built with advanced technologies that enhance quality control measures. This ensures that each product meets the required specifications consistently, reducing the risk of defects and rework.

Market Availability

As the demand for custom metal roll forming machines continues to rise, numerous manufacturers and suppliers are emerging in the market. It's essential for businesses seeking these machines to consider several factors before making a purchase.

- Reputation of the Manufacturer Researching the reputation of the machine manufacturer is vital. Established manufacturers often provide better support services and offer warranties on their machinery.

- Technology and Features The latest roll forming technology, including automation and integration with smart manufacturing systems, can significantly enhance the production process. Therefore, businesses should look for machines equipped with modern features.

- Maintenance and Support It's essential to evaluate the maintenance requirements of a custom roll forming machine. Opting for manufacturers that offer robust support and maintenance services can minimize downtime and ensure continuous operation.

- Cost vs. Value While price is an important consideration, it's essential to balance cost with the value provided. Investing in high-quality custom machines that offer durability and advanced features can yield better returns in the long run.

Conclusion

Custom metal roll forming machines represent a significant advancement in manufacturing technology. By offering tailored solutions, enhanced efficiency, and improved quality control, these machines are invaluable for businesses looking to innovate and stay competitive in their respective markets. As manufacturers explore their options for roll forming machines, investing in custom solutions may provide the best pathway to achieving their production goals while meeting the demands of an ever-changing industry landscape. Whether for construction, automotive, or other industrial applications, custom metal roll forming machines are crucial assets that can drive growth and profitability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025