custom machine for roofing sheet

Custom Machines for Roofing Sheets Enhancing Efficiency and Quality

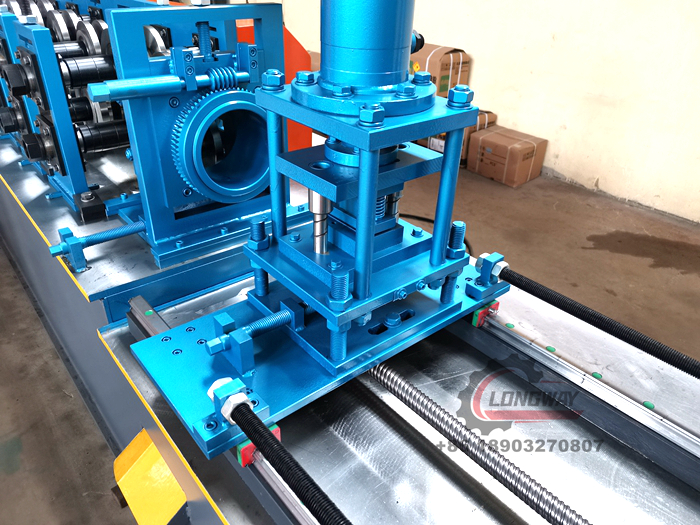

In the construction and manufacturing industry, the demand for high-quality roofing materials is ever-increasing. Roofing sheets play a crucial role in protecting structures from the elements and contribute to the overall aesthetics of buildings. To meet the diverse needs of this market, custom machines specifically designed for producing roofing sheets have emerged as a game-changer. These machines not only improve productivity but also ensure precision and consistency in the manufacturing process.

The Importance of Customization

Every construction project has unique requirements, and the same holds true for roofing sheets. Factors such as material type, thickness, color, and design patterns vary depending on the environmental conditions and architectural preferences. Custom machines allow manufacturers to tailor the production process to fulfill these specific demands. For instance, a machine can be configured to produce corrugated sheets, flat sheets, or even specialized profiles, depending on the client's specifications. This level of customization is essential for maintaining a competitive edge in an industry where client satisfaction directly impacts success.

Advanced Technology Integration

Modern custom machines for roofing sheet production incorporate advanced technologies that enhance efficiency and accuracy. Computer Numerical Control (CNC) systems, for example, enable precise machining and cutting processes. This technology minimizes waste and ensures that each piece produced meets stringent quality standards. Additionally, automation features in these machines facilitate faster production rates, reducing labor costs and turnaround times for projects.

Moreover, many custom machines are designed to accommodate various materials including metal, plastic, and composite materials. This versatility allows manufacturers to diversify their product offerings, catering to different market segments ranging from residential buildings to industrial facilities. The ability to switch between materials and adjust production settings seamlessly is a significant advantage provided by custom machinery.

custom machine for roofing sheet

Sustainability Considerations

As the global emphasis on sustainability grows, the roofing sheet manufacturing industry is also evolving to address environmental concerns. Custom machines can be developed with eco-friendly practices in mind, using energy-efficient processes and reducing waste. For example, recycling capabilities can be integrated into the machines to repurpose scrap materials, minimizing the environmental impact. By investing in sustainable custom machines, manufacturers not only comply with regulations but also appeal to environmentally conscious consumers.

The Competitive Advantage

Investing in custom machines for roofing sheet production can significantly boost a manufacturer’s competitive position. By offering varied products tailored to specific market needs, companies can attract a broader customer base. Furthermore, the reliability and efficiency of these machines ensure that production schedules are met without sacrificing quality, thereby enhancing customer satisfaction.

The upfront investment in custom machinery may seem daunting, but the long-term benefits in productivity, quality, and sustainability often outweigh these costs. As disputes over labor shortages and increasing raw material prices continue to challenge the industry, the automation and efficiency offered by custom machines present a viable solution.

Conclusion

In conclusion, custom machines for roofing sheet production represent a crucial advancement in the construction materials sector. By providing tailored solutions, integrating advanced technologies, and addressing sustainability concerns, these machines enhance operational efficiency and product quality. As the industry progresses, embracing such innovations will likely distinguish leading manufacturers in an ever-competitive marketplace. The future of roofing materials is undoubtedly bright, driven by the promise of custom-designed machinery that transforms potential into reality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025