custom light steel roll forming machine

Custom Light Steel Roll Forming Machines Revolutionizing Construction

In the fast-paced world of construction and manufacturing, the demand for efficient and reliable machinery has never been higher. The introduction of custom light steel roll forming machines has significantly transformed the way steel components are produced, allowing for enhanced productivity, cost-effectiveness, and superior quality in the construction industry.

Understanding Roll Forming Technology

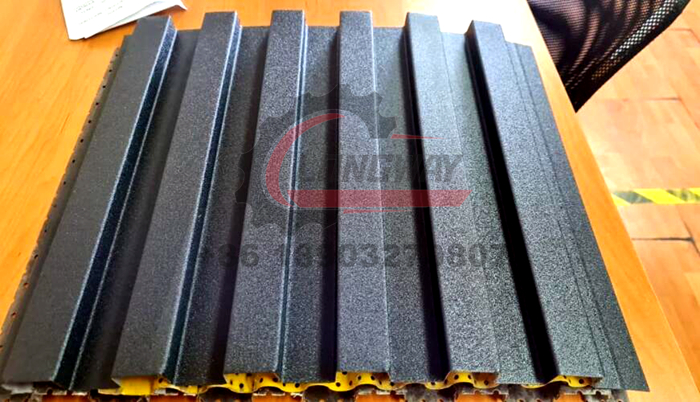

Roll forming is a continuous bending operation in which a long strip of metal, usually steel, is passed through a series of rollers to form the desired shape. This process is highly efficient and can produce complex shapes quickly, making it ideal for a wide range of applications. Custom light steel roll forming machines are specifically designed to handle lightweight steel materials while providing flexibility to customize designs according to client specifications.

Benefits of Customization

One of the key advantages of investing in a custom light steel roll forming machine is the ability to tailor the machinery to meet specific production needs. Clients can specify parameters such as the width, thickness, and profile of the steel, allowing for a level of personalization that mass-produced machines simply cannot offer. This customization can lead to considerable cost savings, as manufacturers can produce exactly what they need without excess waste or unnecessary overhead.

Additionally, custom machines can be designed for specific applications, whether for residential construction, commercial buildings, or industrial facilities. This versatility enables businesses to diversify their offerings and cater to a wider range of projects, improving their competitiveness in the market.

Enhancing Production Efficiency

Custom light steel roll forming machines streamline the manufacturing process. By reducing the number of operations needed to produce a specific component, these machines minimize operational costs and lead times. The roll forming process is considerably faster than traditional methods, enabling manufacturers to meet tight deadlines without sacrificing quality.

custom light steel roll forming machine

Moreover, the automated nature of modern roll forming machines ensures consistent quality across production runs

. This reliability reduces the likelihood of defects and minimizes material waste, ultimately leading to higher profit margins for manufacturers.Environmental Impact

As sustainability becomes an increasingly important consideration in construction, custom light steel roll forming machines offer an eco-friendly solution. Steel is a highly recyclable material, and the efficiency of roll forming minimizes waste during production. Manufacturers can also implement energy-saving technologies in their custom machines, further reducing the environmental footprint of the construction process.

By utilizing light steel, builders can create structures that are not only robust but also contribute to energy efficiency throughout their lifecycle. Lightweight materials lead to reduced energy consumption during transportation and construction, making them an attractive option for environmentally conscious projects.

Applications Across Industries

The applications of custom light steel roll forming machines are vast and varied. In the residential sector, they are used to manufacture components like roof trusses, wall studs, and metal framing. In commercial construction, they provide solutions for purlins, girders, and other structural elements. Additionally, the machinery is beneficial for fabricating components for prefabricated buildings, which have gained popularity due to their cost-saving and time-efficient properties.

The automotive and manufacturing industries also leverage light steel roll forming for producing components such as brackets, reinforcements, and chassis parts. The ability to create lightweight yet sturdy parts is crucial for improving fuel efficiency and performance in modern vehicles.

Conclusion

In conclusion, custom light steel roll forming machines are revolutionizing the construction and manufacturing industries by providing tailored solutions that enhance productivity, reduce costs, and promote sustainability. Their flexibility in design and efficiency in production make them an invaluable asset for modern builders and manufacturers. As the industry continues to evolve, the importance of such innovative machinery will only increase, shaping the future of construction in fascinating ways. Investing in these cutting-edge machines is not just a smart business decision; it is a step toward a more efficient, sustainable, and customizable construction process that can meet the demands of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025