custom light keel roll forming machine

Custom Light Keel Roll Forming Machine Revolutionizing Construction with Precision and Efficiency

In the ever-evolving landscape of construction and manufacturing, the introduction of advanced machinery has transformed traditional methods into innovative, efficient processes. One of the most significant advancements in recent years is the custom light keel roll forming machine. This specialized equipment serves a critical role in the creation of light steel keels, which are essential components in modern construction, particularly in metal stud framing for drywall and ceiling systems.

Understanding the Custom Light Keel Roll Forming Machine

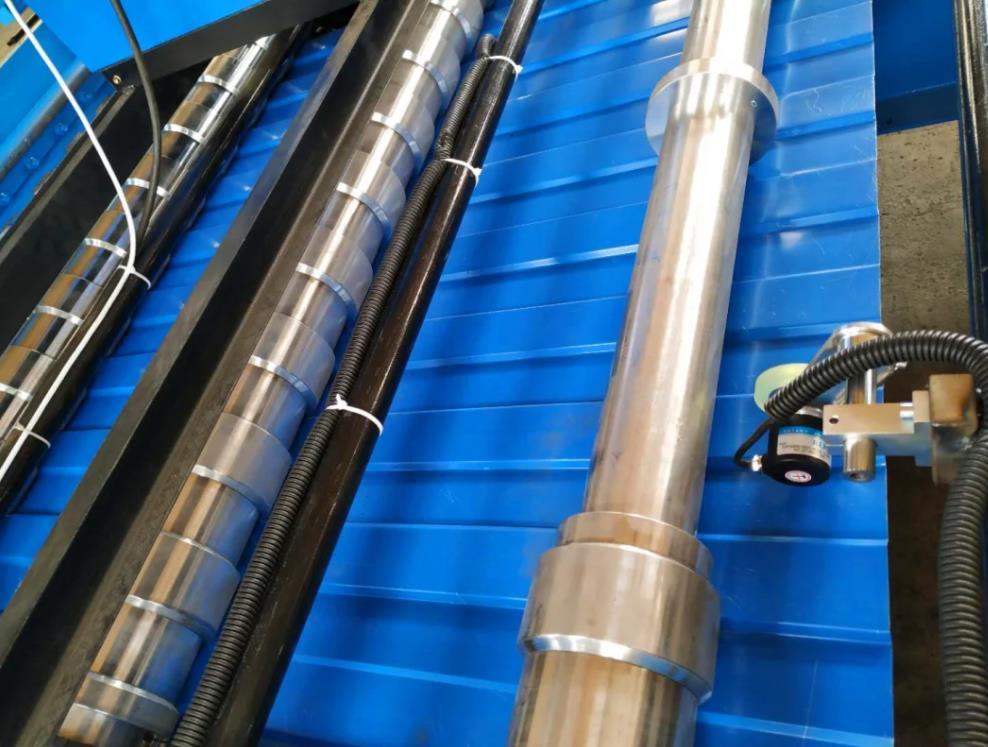

A custom light keel roll forming machine is designed to produce high-quality light steel keels from steel coils. The process begins with feeding a coil of steel into the machine, which then shapes it into the desired profile as it passes through a series of rollers. The machine is capable of producing various profiles and sizes, making it highly flexible and adaptable to different construction requirements.

These machines operate on a principle that combines precision engineering with high-speed production capabilities. The rolled products exhibit excellent dimensional accuracy, a characteristic that is crucial for the structural integrity of building frameworks. Furthermore, the customizability of these machines allows manufacturers to create specific profiles tailored to the unique needs of their projects, enhancing operational efficiency.

Advantages of Customization

One of the standout features of the custom light keel roll forming machine is its ability to be tailored to meet specific production needs

. This customization is crucial for projects that demand unique specifications or where the standard sizes do not suffice. By employing a customized machine, manufacturers can significantly reduce waste and optimize material usage, as the production process is designed to create the exact dimensions required with minimal scrap.Additionally, the flexibility of these machines enables quick changes in production runs. Manufacturers can easily switch from one profile to another, accommodating a broad range of applications without extensive downtime. This adaptive capability is particularly beneficial in today's fast-paced construction environment, where project timelines are critical.

custom light keel roll forming machine

Increased Production Efficiency

The efficiency gains achieved through the use of a custom light keel roll forming machine are substantial. These machines operate at high speeds, allowing for the rapid production of components with uniform quality. Automated systems also minimize manual labor, reducing the risk of human error and increasing overall safety in the workplace.

Moreover, the integration of modern technology, such as computer numerical control (CNC) systems, enhances the precision and repeatability of the production process. This ensures that every light keel produced meets stringent quality standards, an essential aspect of building regulations and codes.

Applications in Construction

The light steel keels produced by these roll forming machines play a vital role in various construction applications. They are widely used in interior framing for partition walls, ceiling grids, and as support structures in various architectural designs. Their lightweight nature makes them ideal for reducing the overall load on buildings while maintaining structural integrity.

Moreover, light steel keels are non-combustible and resistant to pests such as termites, offering durability and longevity that traditional wood framing cannot provide. As the construction industry increasingly shifts towards sustainable and efficient building practices, the demand for steel framing systems is expected to continue to rise.

Conclusion

In summary, the custom light keel roll forming machine represents a significant advancement in manufacturing technology, addressing the construction industry’s demand for precision, efficiency, and customization. By facilitating the production of high-quality light steel keels, these machines not only enhance the overall efficiency of construction processes but also contribute to the creation of safer and more sustainable building practices. As the industry continues to evolve, the role of such innovative machinery will become ever more critical in meeting the challenges of modern construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025