customized double layer roll forming machine

Customized Double Layer Roll Forming Machine A Game Changer in Metal Fabrication

In the realm of metal fabrication, efficiency and versatility are paramount. Industries ranging from construction to automotive are constantly in need of high-quality metal components produced at scale. One innovative solution that has emerged to meet these demands is the customized double layer roll forming machine. This advanced technology not only enhances productivity but also provides a unique approach to manufacturing in various sectors.

What is a Double Layer Roll Forming Machine?

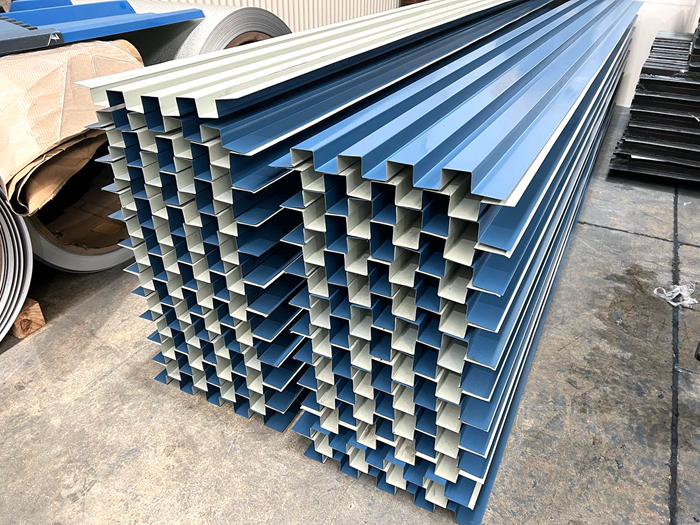

A double layer roll forming machine is designed to produce two different profiles or sheets simultaneously from a single setup. This machine comprises two sets of rollers, one on top of the other, allowing manufacturers to create two distinct layers of metal sheets without the need for multiple machines. This dual capability means that companies can produce more output with less space and reduced operational costs.

Benefits of Customization

The key feature of these machines lies in their customization options. Clients can tailor the specifications according to their unique needs, which ensures that the final product meets specific requirements. Customization can include the choice of materials, thickness, width, and the shapes of the profiles being formed. Such flexibility allows businesses to diversify their product offerings and respond promptly to market demands.

Enhanced Efficiency and Cost-Effectiveness

customized double layer roll forming machine

Time is money in any industry, and the double layer roll forming machine significantly reduces manufacturing time. By producing two profiles in one pass, companies can double their productivity without doubling their equipment investment. Moreover, the reduced number of machines translates to lower maintenance costs and less energy consumption.

Applications Across Industries

The applications for a customized double layer roll forming machine are as diverse as the industries that employ them. In construction, these machines can produce roof panels, wall panels, and various structural components. The automotive industry utilizes them for manufacturing parts such as brackets, channels, and frames. Additionally, the machine's ability to produce products that cater to different industries means that businesses can expand their reach and explore new markets.

Quality Assurance and Technology

Modern double layer roll forming machines are equipped with advanced technology that ensures consistent quality and precision in production. Many come with digital controls and automation features that facilitate easy operation and monitoring of the manufacturing process. This technological integration helps minimize errors and improve overall product quality, adhering to international standards.

Conclusion

The customized double layer roll forming machine represents a significant advancement in metal fabrication. Its ability to produce two layers of different profiles simultaneously not only enhances productivity but also allows businesses to adapt to changing market demands. By investing in such technology, companies can reduce costs, improve efficiency, and ensure high-quality output. As industries continue to evolve, the need for innovative solutions like the double layer roll forming machine will only grow, making it a vital tool for any metal fabrication operation. Embracing this technology is not just a choice; it's a strategic move towards a more efficient and profitable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025