Customized Corrugated Roof Sheet Roll Forming Machine for Efficient Production and Versatile Applications

Custom Corrugated Roof Sheet Roll Forming Machine Revolutionizing Construction

The construction industry is constantly evolving, with demands for efficiency, durability, and cost-effectiveness at an all-time high. One of the tools leading the charge in this transformation is the custom corrugated roof sheet roll forming machine. This advanced machinery streamlines the production of corrugated roofing sheets, which are essential in a variety of construction applications, from residential homes to commercial buildings and industrial warehouses.

Understanding Roll Forming Technology

At the heart of a corrugated roof sheet roll forming machine is the roll forming process. This continuous bend process involves feeding a metal coil through a series of rollers that progressively shape it into a desired profile. For corrugated sheets, the end result is a series of raised and lowered sections that enhance the sheet's structural integrity and aesthetic appeal. Customized configurations allow manufacturers to produce sheets of various sizes, thicknesses, and designs, catering to specific project requirements.

Benefits of Customization

One of the most significant advantages of custom roll forming machines is their capacity for customization. The ability to design and fabricate roofing sheets according to precise specifications is invaluable for construction companies. Whether a project requires specific dimensions, unique corrugation patterns, or differing material types, a custom roll forming machine can adapt to meet these needs. This flexibility not only enhances design creativity but also minimizes waste, as manufacturers can optimize materials for each project.

Quality and Precision

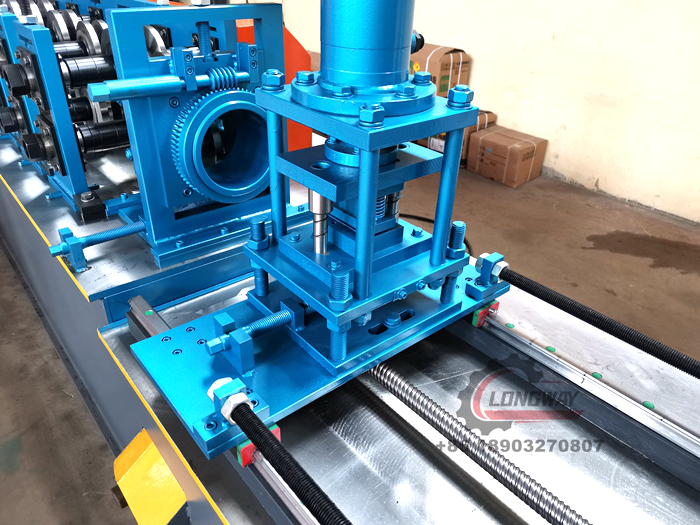

custom corrugated roof sheet roll forming machine

Quality control is another critical factor in the construction industry. Custom corrugated roof sheet roll forming machines are designed to produce consistent and precise results, minimizing human error and ensuring high-quality outputs. Equipped with advanced technology, such as computerized controls and sensors, these machines monitor the production process in real time, allowing for adjustments on the fly. This level of precision ensures that the roofing sheets meet the required standards and specifications, ultimately resulting in a superior product that withstands the test of time.

Cost-Effectiveness

In the competitive construction market, cost-effectiveness plays a significant role. Custom roll forming machines streamline production, reducing labor costs and minimizing material waste. By eliminating the need for multiple processes that are traditionally required to create corrugated sheets, companies can save both time and money. Furthermore, the durability of the finished product means that clients are less likely to incur maintenance costs in the long run, making it a wise investment.

Environmental Impact

Sustainability has become a major concern in modern construction practices. The use of roll forming machines contributes positively to environmental goals by minimizing waste and maximizing material efficiency. Operators can recycle leftover materials, and the production process often consumes less energy compared to traditional manufacturing methods. This aligns with the growing demand for eco-friendly building solutions, making custom corrugated roofing an attractive option for environmentally conscious projects.

Conclusion

In conclusion, the custom corrugated roof sheet roll forming machine represents a significant advancement in the construction industry. Its ability to produce high-quality, customized roofing sheets efficiently and affordably meets the diverse needs of modern construction projects. As this technology continues to evolve, it promises to play a crucial role in shaping the future of building design and construction, contributing to both economic and environmental sustainability. For builders and contractors looking to stay ahead in a competitive market, investing in such advanced machinery is undoubtedly the way forward.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025