customizable light keel roll forming machine

Customizable Light Keel Roll Forming Machine Revolutionizing Lightweight Steel Construction

In the world of construction and manufacturing, efficiency and precision are the cornerstones of success. With the increasing demand for lightweight yet sturdy structures, the roll forming industry has seen significant innovation, particularly with the advent of customizable light keel roll forming machines. These specialized machines play a crucial role in shaping lightweight steel materials into varied profiles, offering flexibility and speed to construction projects.

Understanding Light Keels

Light keels are crucial components in modern construction, especially in metal framing systems. These thin, elongated structures provide the necessary strength and support for ceilings, walls, and other architectural elements while keeping the overall weight of the building to a minimum. Traditionally, creating these keels involved labor-intensive processes that could lead to inconsistencies in product quality. However, with the introduction of customizable light keel roll forming machines, manufacturers can now produce high-quality keels with precision and efficiency.

How Customizable Roll Forming Machines Work

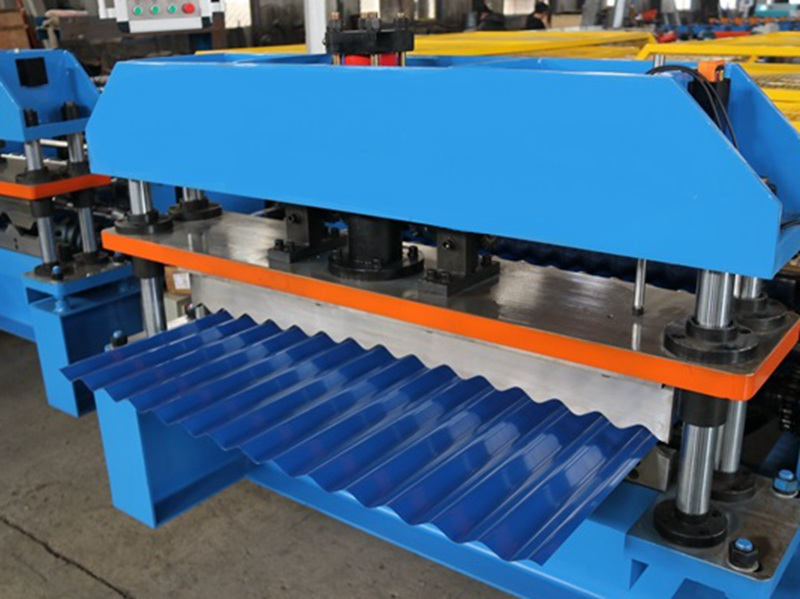

The customizable light keel roll forming machine operates through a continuous process that transforms flat metal strips into configured profiles. These machines consist of several key components the uncoiler, roll forming station, cutting station, and control system.

1. Uncoiler The process begins with the uncoiler, which feeds the flat metal sheet into the roll forming machine. This component is critical as it ensures a smooth and consistent flow of material.

2. Roll Forming Station The metal strip then passes through a series of rollers, each designed to bend and shape the material incrementally. The design of these rollers can be customized, allowing manufacturers to create unique profiles tailored to specific construction needs.

3. Cutting Station After the metal has been formed into the desired shape, it is directed to the cutting station, where it is cut to the specified lengths. This ensures that each piece produced is not only precise but also meets the exact requirements of the project.

customizable light keel roll forming machine

4. Control System The integration of advanced technology allows operators to adjust the machine parameters easily. This means that manufacturers can quickly switch between different profiles without significant downtime, enhancing production efficiency and flexibility.

Benefits of Using Customizable Light Keel Roll Forming Machines

1. Efficiency Automated processes reduce labor costs and production time significantly. Project timelines can be shortened, allowing constructions to progress quickly.

2. Quality Control With the precision offered by these machines, the quality of the light keels produced is consistently high. This uniformity in dimensions and strength is critical for structural integrity.

3. Customization The ability to tailor the production process means that manufacturers can respond swiftly to specific customer demands or project requirements, addressing the diverse needs of the construction industry.

4. Cost-effectiveness Reducing material waste and labor costs directly translates to better profit margins for manufacturers, making their services more competitive.

Conclusion

The customizable light keel roll forming machine is a gamechanger in the construction industry, particularly in the manufacturing of lightweight steel components. By streamlining production processes and enhancing the customization of profiles, these machines help meet the growing demand for efficient, high-quality construction materials. As the industry continues to embrace innovation, the role of advanced machinery like the customizable light keel roll forming machine is poised to expand further, setting new standards for quality and efficiency in building practices worldwide. As companies seek sustainable solutions to meet modern architectural challenges, the significance of these machines cannot be overstated, driving both productivity and excellence in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025