Customizable Panel Roll Forming Machines for Efficient Production of High-Quality Building Components

Understanding Panel Roll Forming Machines A Key Innovation in Metal Fabrication

In the world of metal fabrication, efficiency and precision are fundamental. One of the most innovative machines that have revolutionized this industry is the panel roll forming machine. This machine is essential for producing various panels used in construction, roofing, and manufacturing industries. By understanding its functionality, benefits, and applications, businesses can leverage this technology to enhance their production processes.

What is a Panel Roll Forming Machine?

A panel roll forming machine is a specialized piece of equipment designed to convert flat metal sheets into specific shapes used in panel production. The process involves feeding coils or sheets of metal through a series of rollers that progressively shape the metal into the desired profile. This machine can create a wide range of products, including wall panels, roof panels, and even components for structural elements like beams and columns.

The operation of a roll forming machine is continuous, meaning that once the initial setup is complete, it can run for extended periods, producing uniform panels without interruption. This characteristic is one of the reasons it is favored in industries that demand high-volume production.

The Process of Roll Forming

The roll forming process starts with the selection of the appropriate metal material, such as galvanized steel, stainless steel, or aluminum. The chosen material is then fed into the machine, where it passes through multiple sets of rollers. Each roller imparts a specific contour, and through successive stages, the metal gradually takes shape.

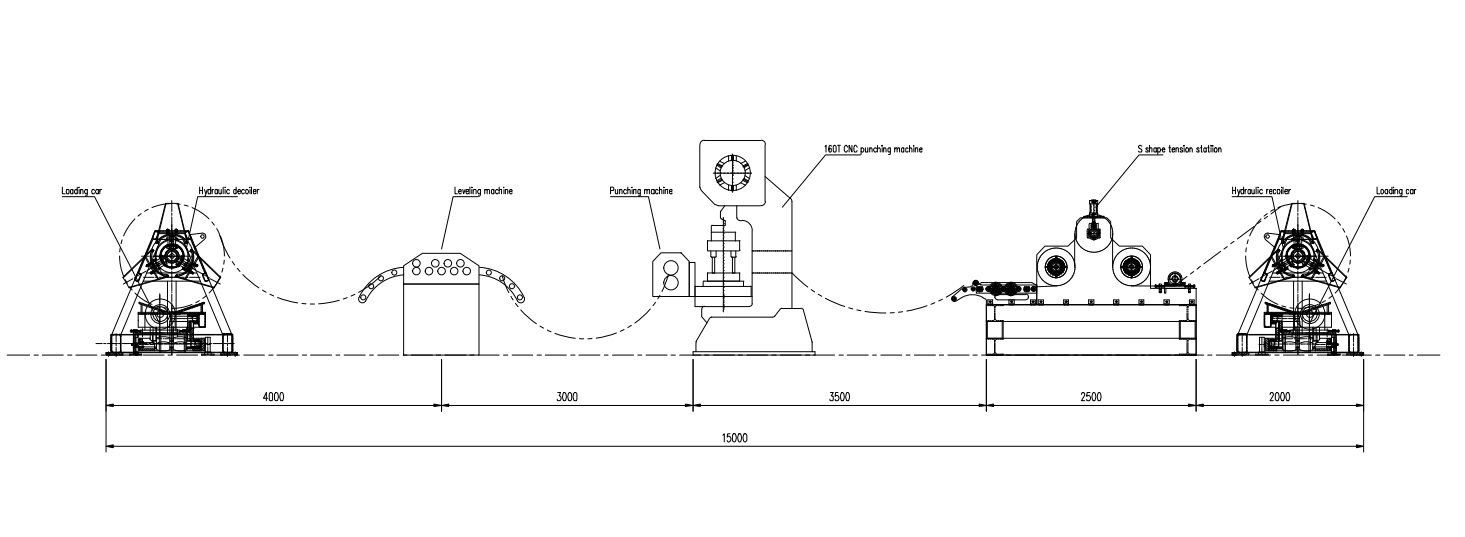

Once the metal is formed, it may undergo additional processes, such as cutting to length, punching, or adding holes for fastening. The final products are then inspected for quality assurance before being packaged for distribution or use in construction projects.

Advantages of using Panel Roll Forming Machines

panel roll forming machine

1. Efficiency One of the standout benefits of panel roll forming machines is their speed and efficiency. Once set up, these machines can produce many panels in a short amount of time, greatly enhancing production rates.

2. Consistency and Precision Roll forming ensures that each panel produced maintains consistent dimensions and quality. This uniformity is critical in construction and manufacturing, where precision affects the fit and overall performance of assembled products.

3. Material Utilization The roll forming process is designed to minimize waste. The continuous nature of the machine means that very little material is scrapped throughout the forming process, making it an environmentally friendly choice.

4. Versatility Panel roll forming machines are versatile and adaptable to produce different profiles suited to various applications. Manufacturers can easily change the die or roller configuration to switch between products.

5. Cost-Effectiveness While the initial investment for a panel roll forming machine can be significant, the long-term savings in labor, material usage, and production time often outweigh the costs. Additionally, the durability of the machines means they can operate for years with minimal maintenance.

Applications of Panel Roll Forming Machines

Panel roll forming machines are widely used across several sectors. In the construction industry, they are indispensable for manufacturing roof panels and wall cladding, providing not only aesthetic value but also structural integrity. Additionally, industries such as automotive and appliance manufacturing utilize these machines to produce components that require specific shapes and sizes.

In conclusion, the panel roll forming machine represents a significant advancement in the metal fabrication process. Its efficiency, precision, and versatility make it an essential tool for manufacturers looking to optimize their production capabilities. As industries continue to evolve, the role of such machines in streamlining operations and reducing costs will only become more prominent. Investing in a panel roll forming machine could be a game-changer for businesses striving to meet the demands of today's competitive markets.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025