custom iron roof sheet making machine

Custom Iron Roof Sheet Making Machine Revolutionizing Roofing Solutions

In the ever-evolving construction industry, the demand for durable and aesthetically pleasing roofing materials is at an all-time high. Custom iron roof sheet making machines have emerged as a pivotal solution for manufacturers aiming to meet this demand efficiently and economically. These machines not only streamline the production process but also ensure that the various needs of clients are catered to with precision and quality.

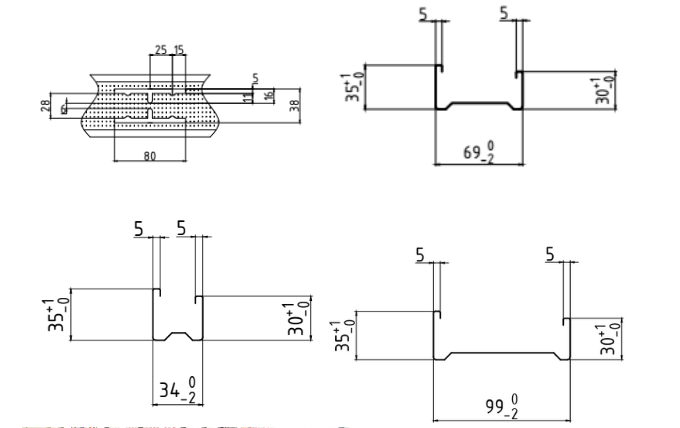

Traditionally, roofing solutions were limited to a few materials, but advancements in technology have broadened the horizons, enabling the production of iron roof sheets that combine strength, durability, and versatility. Customization is essential in today’s market, where customers seek roofing sheets that fit specific architectural styles and functional requirements. Iron roof sheet making machines facilitate this by allowing manufacturers to tailor the dimensions, thickness, and designs of the roof sheets according to individual client specifications.

One of the most significant benefits of utilizing a custom iron roof sheet making machine is the efficiency it brings to the production line. These machines are designed with advanced technology that enhances the speed and quality of output. With automated features, manufacturers can produce large quantities of roof sheets, significantly reducing labor costs and production time. The ability to operate at high speeds without compromising quality is a game-changer, especially in construction projects that require timely delivery of materials.

custom iron roof sheet making machine

Moreover, customization capabilities enable manufacturers to explore various finishes and coatings, catering to a diverse clientele. Whether it’s a textured finish for aesthetic appeal or a galvanized coating for enhanced rust resistance, the flexibility offered by these machines ensures that producers can meet the varying demands of their customers. This adaptability is crucial for standing out in a competitive market where unique offerings can capture more attention.

Environmental sustainability is another aspect where custom iron roof sheet making machines shine. Manufacturers can optimize material usage, minimizing waste through precise cutting and shaping processes. Additionally, these machines can incorporate recycled materials, contributing to a greener production cycle. As the construction industry increasingly focuses on sustainability, adopting such equipment aligns with ecological goals while maintaining profitability.

Investing in a custom iron roof sheet making machine also presents long-term financial benefits. Initial costs may be substantial, but the return on investment is substantial due to increased production efficiency and reduced labor expenses. Furthermore, as businesses expand and the demand for diverse roofing options grows, having the capability to produce customized sheets will provide a significant competitive edge.

In conclusion, the custom iron roof sheet making machine is a transformative tool in the roofing materials industry. By focusing on efficiency, customization, and sustainability, these machines allow manufacturers to adapt to changing market demands while ensuring high-quality outputs. As new building trends emerge, investing in such technology will undoubtedly enable businesses to thrive in a challenging yet rewarding landscape. Embracing the innovation inherent in these machines is not just a step toward modernization; it’s a leap toward securing a prominent position in the future of construction and roofing solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025