custom highway guardrail forming machine

Custom Highway Guardrail Forming Machine Enhancing Safety and Efficiency

In today's rapidly evolving infrastructure landscape, the importance of road safety has never been more paramount. Among the myriad of advancements aimed at safeguarding drivers and pedestrians alike, the custom highway guardrail forming machine stands out as a pivotal innovation. Designed specifically for the efficient production of guardrails, this machine embodies both technological sophistication and strategic utility, ensuring roads are equipped with long-lasting protective barriers.

The Importance of Guardrails

Highway guardrails serve as vital defensive structures designed to prevent vehicles from veering off the road, protecting against accidents related to steep drops, sharp turns, and roadside hazards. These robust barriers not only mitigate collision impacts but also serve to guide vehicles safely along their intended paths. As traffic volumes increase and road systems become more complex, the demand for high-quality, durable guardrails has surged, prompting the need for advanced manufacturing solutions.

Customization Meeting Diverse Needs

One of the standout features of the custom highway guardrail forming machine is its ability to be tailored to meet specific project requirements. Different regions and road types may necessitate varying guardrail specifications, including height, length, material, and design. By employing a custom guardrail forming machine, manufacturers can efficiently produce products that comply with local regulations and meet the unique safety needs of individual projects without compromising quality or performance.

Customization isn’t merely about adjusting sizes but also involves integrating technology that enhances the machine’s capabilities. Features such as variable speed controls and automated measurement systems ensure that every piece produced adheres to precise specifications, thus minimizing waste and maximizing efficiency.

Advanced Technology in Manufacturing

custom highway guardrail forming machine

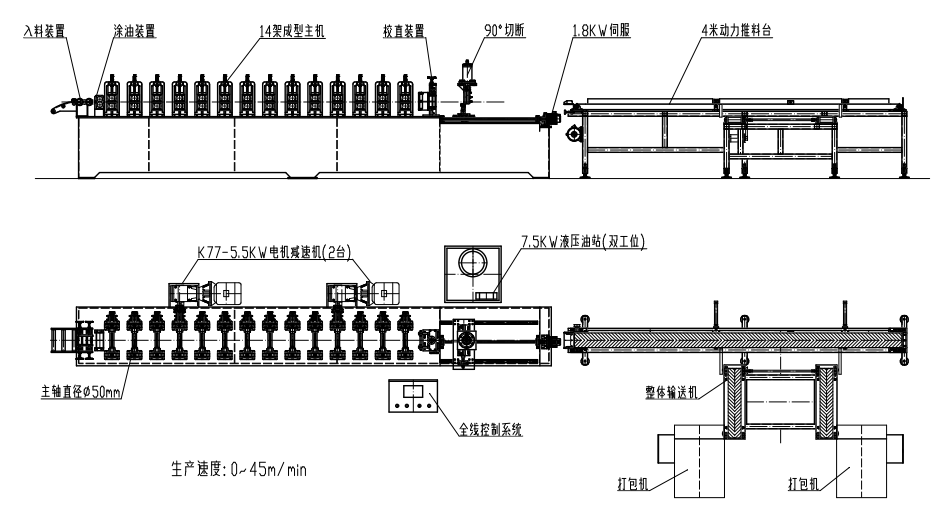

Modern custom highway guardrail forming machines are equipped with cutting-edge technology that streamlines the manufacturing process. Advanced software interfaces allow operators to design and modify guardrail sizes and shapes directly from a computer, facilitating rapid prototyping and production adjustments. Furthermore, automation in the forming process reduces labor costs while increasing output efficiency, enabling manufacturers to meet high demand without sacrificing safety or quality.

Laser cutting and welding technologies incorporated within these machines also guarantee precise and strong joints, which are essential for the durability of guardrails. By utilizing high-quality materials and advanced forming techniques, manufacturers can ensure that the guardrails produced can withstand the rigors of vehicular impact, extreme weather conditions, and other environmental factors.

Economic Advantages

Investing in a custom highway guardrail forming machine offers several economic benefits. The ability to produce guardrails on demand significantly reduces lead times, making it easier for contractors to adhere to project schedules. This swift turnaround is crucial in today's fast-paced construction environment, where delays can translate into increased costs.

Moreover, the ability to manufacture guardrails in-house eliminates dependence on external suppliers, providing manufacturers with greater control over quality and supply chain logistics. This autonomy can lead to cost savings on procurement, transportation, and storage, further enhancing the overall profitability of guardrail production operations.

Conclusion

As our roadways continue to evolve in complexity and traffic volume, the need for reliable safety solutions remains vital. The custom highway guardrail forming machine is not only a testament to the advancements in manufacturing technology but also a critical component in ensuring the safety of our transportation infrastructure. By providing tailored solutions that meet diverse specifications, these machines play an integral role in enhancing road safety, minimizing risks, and promoting economic efficiency in guardrail production. Investing in such innovative machinery is an investment in a safer, more reliable future for our highways.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025