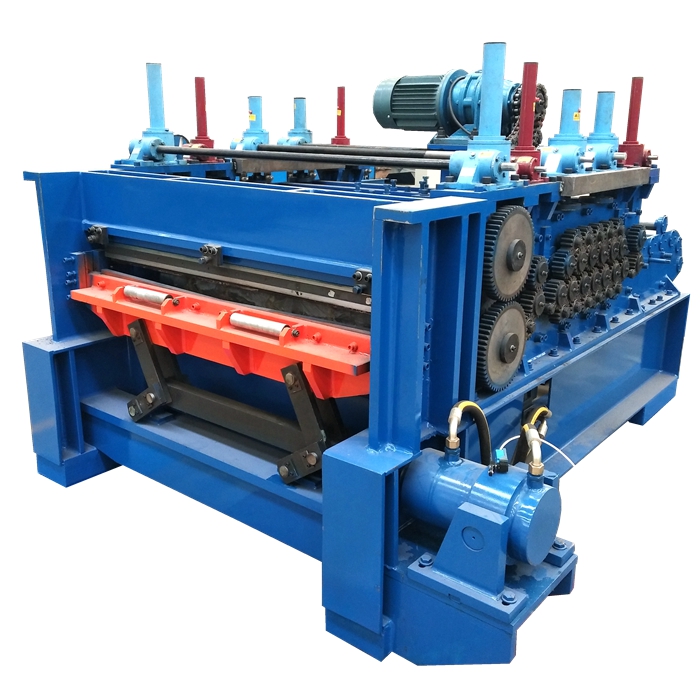

custom gypsum channel making machine

Custom Gypsum Channel Making Machine Revolutionizing Gypsum Production

In the ever-evolving construction industry, the demand for high-quality materials has consistently risen. Among these materials, gypsum has emerged as a favorite due to its excellent properties, including fire resistance, thermal insulation, and soundproofing. As a result, the production of gypsum products has become a booming sector, with the custom gypsum channel making machine playing a pivotal role in this growth.

What is a Custom Gypsum Channel Making Machine?

A custom gypsum channel making machine is a specialized piece of equipment designed to produce gypsum channels, which are essential components in various construction applications. These machines utilize advanced technology to efficiently mold and shape gypsum into channels that meet specific design requirements. The customization aspect allows manufacturers to adapt the machine settings to produce different sizes and shapes, catering to the unique needs of their clients.

Advantages of Using a Custom Gypsum Channel Making Machine

1. Precision and Efficiency

One of the standout advantages of using a custom gypsum channel making machine is its ability to produce high-quality products with precision. The machine's automated features minimize human error, ensuring that each channel is crafted to the exact specifications. This precision is vital in construction, where even minor discrepancies can lead to significant issues during installation.

2. Cost-Effectiveness

Investing in a custom gypsum channel making machine can lead to considerable cost savings in the long run. By producing channels in-house, companies can significantly reduce their material costs and eliminate the need for outsourcing. Moreover, the efficiency of the machine significantly reduces labor costs by automating much of the production process.

3. Flexibility to Adapt to Market Demands

custom gypsum channel making machine

The construction industry is dynamic, with trends and demands constantly changing. A custom gypsum channel making machine allows manufacturers to quickly adapt to these market fluctuations. By altering the machine settings, they can produce different styles and sizes of channels, thereby meeting the evolving needs of their clients without requiring extensive modifications to their production lines.

4. Enhanced Quality Control

With in-house production using custom machines, manufacturers have greater control over the quality of their products. This means they can quickly identify and rectify any issues, ensuring that only the best gypsum channels reach the market. Enhanced quality control is crucial in maintaining a good reputation and ensuring customer satisfaction.

The Technological Edge

Modern custom gypsum channel making machines are equipped with innovative technologies that improve production capabilities. Features such as computer numerical control (CNC) allow for intricate designs and precise cuts. Additionally, some machines incorporate eco-friendly technologies, which minimize waste and reduce the environmental impact of gypsum production.

Applications of Gypsum Channels

Gypsum channels are commonly used in a variety of construction applications. They serve as support structures for ceilings and walls, providing stability and fire resistance. Furthermore, gypsum channels are also used in HVAC installations, where they help in creating efficient duct systems. The versatility of these channels makes them an essential component in residential, commercial, and industrial buildings.

Conclusion

The custom gypsum channel making machine stands at the forefront of advancements in the construction material production industry. Its ability to produce high-quality, precisely molded gypsum channels with efficiency and flexibility is transforming the way manufacturers operate. As the demand for gypsum products continues to rise, investing in such innovative machinery will not only enhance production capabilities but also contribute to the overall quality of construction projects.

In summary, the integration of custom gypsum channel making machines into production lines is a strategic move for manufacturers looking to stay competitive in the market. With ongoing improvements in technology and a growing emphasis on sustainability, the future of gypsum production looks promising. As the industry evolves, those who invest in precision and efficiency will undoubtedly lead the way in delivering superior products to the construction sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025