Custom Glazed Sheet Roll Forming Equipment for High-Quality Production

The Role of Custom Glazed Sheet Roll Forming Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the demand for high-quality building materials has surged, particularly in the construction and architectural sectors. One of the key innovations that have revolutionized the production of such materials is the custom glazed sheet roll forming machine. This advanced technology not only streamlines the manufacturing process but also enhances the diversity and quality of architectural products available today.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel or aluminum, is fed through a series of rollers that gradually shape it into the desired profile. This technique is particularly effective for producing uniform, high-quality products, such as glazed sheets used in roofing, wall panels, and other architectural applications.

A custom glazed sheet roll forming machine takes this process a step further by enabling manufacturers to create tailored profiles that meet specific design requirements. This flexibility is paramount in today's market, where customization is often a key selling point for builders and architects.

Advantages of Custom Glazed Sheet Roll Forming Machines

1. Precision Manufacturing One of the foremost advantages of these machines is their ability to produce highly precise products. With advanced computer numerical control (CNC) technology, manufacturers can create complex shapes and designs that were previously unattainable with traditional methods. This precision not only enhances the aesthetic appeal of the finished product but also ensures proper fit and functionality in construction applications.

2. Material Efficiency Custom roll forming machines are designed to minimize waste during the production process. By using a continuous strip, manufacturers can optimize the use of materials, leading to cost savings and a lower environmental impact. The ability to produce glazed sheets with varying thicknesses and finishes further enhances material efficiency.

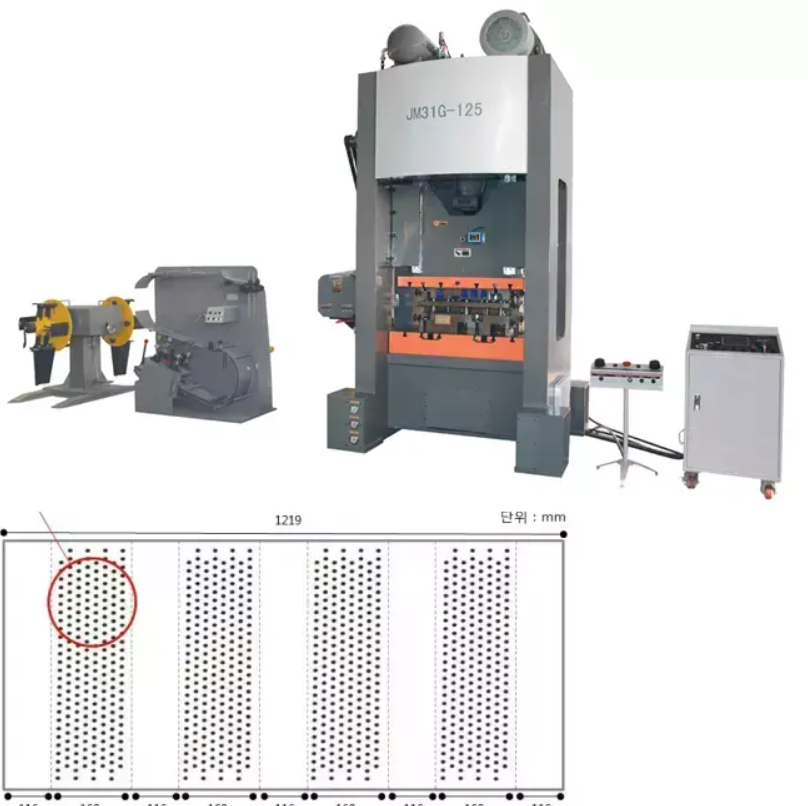

custom glazed sheet roll forming machine

3. Versatility These machines can produce a wide range of profiles, including standing seam roofing, wall cladding, and decorative elements. This versatility allows manufacturers to cater to diverse market demands and project requirements, positioning them as one-stop solutions for contractors and builders.

4. Speed and Scalability With the capacity to operate continuously at high speeds, custom glazed sheet roll forming machines significantly reduce production times. This efficiency is crucial for meeting tight deadlines in the construction industry, where timely delivery can make a substantial difference in project completion.

5. Enhanced Durability Modern glazed sheets produced using roll forming technology are often more durable than those made through traditional methods. The controlled production process ensures a consistent finish, making these sheets resistant to corrosion, impact, and other environmental factors, thereby extending their lifespan.

Applications in the Construction Industry

Custom glazed sheet roll forming machines play a vital role in various applications within the construction sector. Roof systems, exterior wall panels, and decorative facade elements all benefit from the precision and quality offered by this technology. Additionally, as architectural trends shift towards more innovative and sustainable designs, the ability to produce custom profiles will become increasingly important.

Conclusion

In conclusion, the introduction of custom glazed sheet roll forming machines has transformed the manufacturing of architectural materials. By providing manufacturers with the ability to create high-quality, precise, and customized building materials, these machines are helping to meet the growing demands of the construction industry. As technology continues to advance, it is likely that we will see even more innovative uses for roll forming, further cementing its position as a crucial component in modern manufacturing processes. Embracing this technology not only contributes to operational efficiency but also opens doors to creative possibilities in architectural design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025