custom false ceiling channel making machine price

The Cost of Custom False Ceiling Channel Making Machines

In the realm of modern construction and interior design, false ceilings have gained immense popularity due to their aesthetic appeal and functional advantages. To meet the growing demand for these architectural elements, businesses have turned towards investing in machinery that can efficiently manufacture false ceiling channels. One such vital piece of equipment is the custom false ceiling channel making machine. This article explores the various factors influencing the price of these machines and their significance in the construction industry.

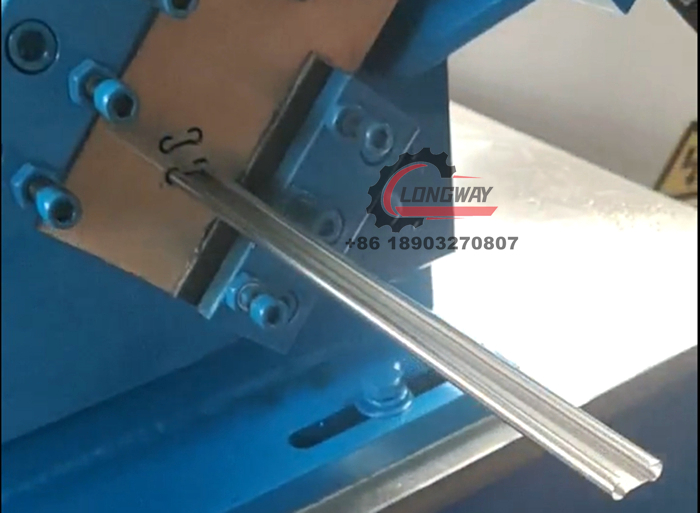

Understanding Custom False Ceiling Channel Making Machines

False ceiling channel making machines are specialized tools designed to produce channels that serve as the framework for false ceilings. These channels are essential for supporting the ceiling panels and can be made from various materials including metal, gypsum, and other composites. A custom machine allows manufacturers to tailor the specifications based on project requirements, providing versatility in design and application.

Price Influencers

The price of custom false ceiling channel making machines can vary widely depending on several factors

1. Machine Specifications The technical specifications of the machine, such as its production capacity, automation level, and material compatibility, play a significant role in determining the cost. More advanced machines that incorporate efficiency-enhancing technologies tend to be more expensive.

2. Brand and Manufacturer The reputation of the manufacturer can significantly affect pricing. Established brands known for quality and durability may charge a premium, while newer or less known manufacturers may offer competitive pricing.

custom false ceiling channel making machine price

3. Customization Features The more customized the machine, the higher the cost. Features such as adjustable settings for different channel sizes, software for design and processing, and specialized tooling can add to the overall expense.

4. Market Demand Fluctuations in demand for false ceiling channels can influence machine prices. During construction booms, prices may rise due to increased demand for machinery that can meet production needs.

5. Costs of Raw Materials The prices of the raw materials that machines are designed to work with can also impact their cost. If materials become more expensive, manufacturers may pass these costs onto consumers, reflecting in the machinery prices.

6. Geographic Location The location of the buyer can affect shipping costs, tariffs, and import duties, which in turn influence the total price of the machine. Local manufacturers may offer more competitive prices due to reduced shipping fees.

Conclusion

Investing in a custom false ceiling channel making machine is a strategic decision that can enhance production efficiency and product quality in the construction industry. While the pricing of these machines varies widely based on specifications, manufacturing brand, and market conditions, it is essential for buyers to evaluate their unique needs and budget carefully.

As the demand for stylish and functional interior spaces continues to increase, investing in high-quality machinery becomes crucial. Prospective buyers should consider not only the purchase price but also the return on investment that comes from enhanced capacity and functionality. With the right equipment, businesses can better meet customer expectations, streamline operations, and ultimately thrive in a competitive market.

In conclusion, understanding the factors that contribute to the pricing of custom false ceiling channel making machines is vital for making an informed purchase. By aligning their needs with the right specifications and pricing dynamics, businesses can effectively boost their productivity and market reach.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025