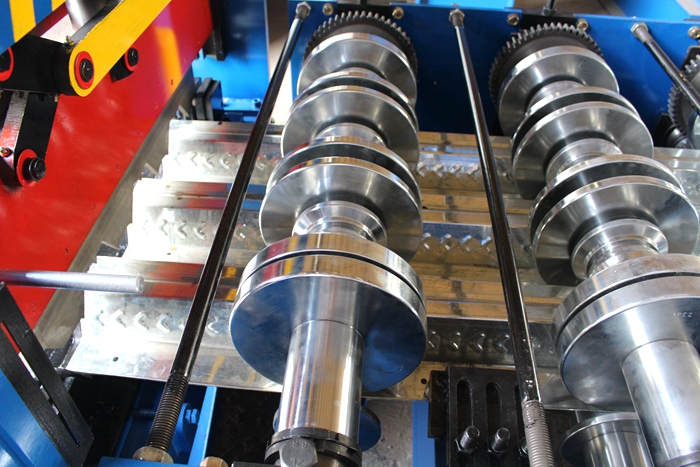

custom drywall roll forming machine

Custom Drywall Roll Forming Machine Revolutionizing Construction

In the ever-evolving construction industry, efficiency and precision are paramount. One of the innovations that have significantly transformed drywall production is the custom drywall roll forming machine. This specialized equipment not only enhances the speed of production but also ensures high-quality output tailored to the specific needs of contractors and builders.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers that progressively shape it into the desired profile. This process is particularly advantageous for producing long lengths of drywall channels, studs, and other components. By employing a custom drywall roll forming machine, manufacturers can create profiles that meet specific loading requirements and aesthetic designs, ultimately resulting in a more reliable and appealing product.

Benefits of Customization

One of the standout features of these machines is the ability to customize. Different construction projects may call for various drywall thicknesses, lengths, and shapes. A custom drywall roll forming machine can be designed to produce an array of profiles in different materials, accommodating different characteristics such as weight, insulation properties, and fire resistance. This flexibility is vital for meeting diverse client specifications and adhering to local building codes.

Enhanced Efficiency

custom drywall roll forming machine

Efficiency is crucial in construction. Traditional methods of drywall production can be time-consuming and labor-intensive. Custom drywall roll forming machines streamline the process, allowing for quicker production cycles. They can operate at high speeds, reducing lead times and enabling construction teams to adhere to tight schedules. This increased efficiency results in lower labor costs and minimized waste, as the machines operate with minimal errors and can utilize raw materials more effectively.

Quality Assurance

Quality is another significant advantage offered by custom drywall roll forming machines. Automated systems ensure precision in the manufacturing process, producing uniform products that diminish the likelihood of defects. Advanced technologies such as Computer Numerical Control (CNC) integrated into these machines further enhance accuracy, allowing for intricate designs and assuring that each piece meets exact specifications. This level of quality is essential to maintaining structural integrity and longevity in building projects.

The Future of Drywall Production

As the construction industry progresses towards sustainability and efficiency, the demand for custom drywall roll forming machines will likely increase. Innovations in materials and production techniques may lead to more environmentally friendly options, catering to the growing focus on sustainable building practices. These machines not only meet today’s demands but also pave the way for the future of construction by adapting to emerging technologies and market needs.

In conclusion, custom drywall roll forming machines represent a significant advancement in the construction sector. They offer exceptional efficiency, tailored solutions, and assurance of quality, making them indispensable to modern drywall production. As the industry continues to innovate, embracing these machines will undoubtedly lead to improved productivity and enhanced building practices. Embracing the future means investing in technology that meets the evolving requirements of construction while maximizing performance and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025