Custom Roll Forming Machines for Unique Deck Designs and Applications

Custom Deck Roll Forming Machines Revolutionizing Construction and Manufacturing

The construction and manufacturing industries have continuously evolved over the years, embracing technology and innovation to enhance efficiency and productivity. One of the standout innovations in these fields is the custom deck roll forming machine. This advanced piece of machinery has become indispensable for producing high-quality metal decking and various other components used in construction projects.

Understanding Roll Forming Technology

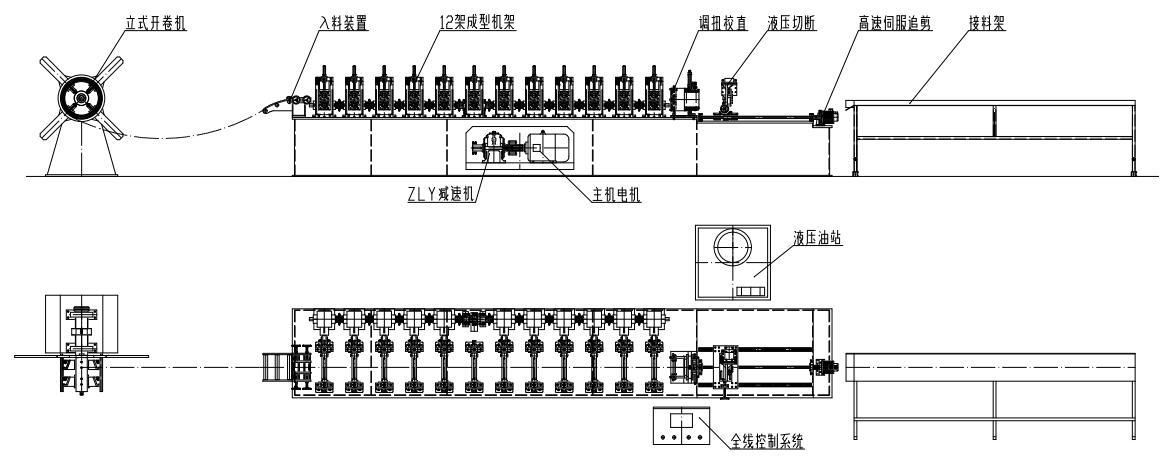

Roll forming is a continuous bending process in which sheet metal is fed through a series of dies to achieve the desired cross-sectional profile. This technique allows for the production of long lengths of metal parts with uniform cross-sections. Custom deck roll forming machines are specifically designed to create metal decking, which is a vital component in modern building structures, including floors, roofs, and walls.

Key Features of Custom Deck Roll Forming Machines

1. Customizability One of the standout features of custom deck roll forming machines is their ability to be tailored to meet specific production requirements. Manufacturers can produce a wide range of decking profiles, ensuring that the final product meets the unique needs of various construction projects. This flexibility not only enhances the capabilities of the manufacturer but also allows for innovation in design and engineering.

2. Efficiency These machines are designed for high-speed operations, significantly reducing production time. The automation of the roll forming process means that manufacturers can produce large quantities of decking quickly without compromising quality. This efficiency translates to lower labor costs and faster project completion times.

3. Precision Custom deck roll forming machines utilize advanced technology to ensure precise dimensions and high-quality finishes. Modern machines are equipped with computer numerical control (CNC) systems that allow for accurate adjustments and monitoring throughout the production process. This precision is crucial, as discrepancies in metal decking can lead to structural issues in construction.

custom deck roll forming machine

4. Durability The materials used in custom deck roll forming machines are designed to withstand rigorous production environments. Many machines are constructed with heavy-duty components that ensure longevity and reliability, reducing maintenance costs and downtime.

5. Versatility Beyond just metal decking, custom roll forming machines can be adapted to produce various products, such as paneling, flashing, and other architectural components. This versatility makes them invaluable for manufacturers looking to diversify their product offerings.

Applications in Construction

Custom deck roll forming machines play a significant role in various construction applications. They are primarily used to produce composite metal decking, which provides structural support and can serve as a surface for pouring concrete. This type of decking is particularly popular in commercial construction for multi-story buildings. Additionally, some manufacturers use these machines to create specialized profiles for roofing systems, allowing for innovative designs that enhance aesthetic appeal while maintaining structural integrity.

The Future of Roll Forming Technology

As the demand for advanced construction materials continues to grow, the future of custom deck roll forming machines looks promising. Innovations such as smart technology integration, automation, and advanced materials research will likely further enhance the capabilities of these machines. Manufacturers who invest in the latest technology will be better positioned to meet the evolving needs of the construction industry.

In conclusion, custom deck roll forming machines represent a significant advancement in construction technology, offering manufacturers the ability to produce high-quality metal decking efficiently and precisely. As the industry continues to evolve, these machines will undoubtedly play a critical role in shaping the future of construction and manufacturing. From enhancing production speeds to providing customization options, custom deck roll forming machines are paving the way for improved building practices and innovative designs.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025