Custom Roll Forming Solutions for Tailored Metal Fabrication and Design Needs

Custom Roll Former Revolutionizing the Manufacturing Process

In the ever-evolving world of manufacturing, the demand for precision and efficiency is paramount. One of the most innovative solutions to emerge in recent years is the custom roll former, a machine that has redefined how metal products are fabricated. Custom roll forming is not just a manufacturing process; it’s a testament to the advancements in technology that allow for tailored solutions to meet specific needs across various industries.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutive sets of rolls. The metal is gradually shaped into the desired cross-sectional profile. Traditionally, this process was used for mass production of standard shapes; however, with the advent of custom roll forming, manufacturers can now produce unique shapes with intricate designs that cater to specific applications.

Customization at Its Core

The primary advantage of a custom roll former lies in its ability to provide bespoke solutions. Industries ranging from construction to automotive are constantly searching for materials that not only fit perfectly but also enhance the overall efficiency of their projects. Custom roll forming allows engineers and designers to specify the exact dimensions, materials, and properties they require. This capability is essential in sectors where standard profiles are insufficient.

For instance, in the construction industry, custom roll formers can create specialized framing components that meet specific structural requirements. This is particularly important in modern architecture, where unique designs often require non-standard components. By utilizing a custom roll former, builders can reduce waste, improve production times, and ensure exact fits, ultimately leading to cost savings and quicker project turnaround times.

Technological Advancements

Innovation in custom roll formers has been driven by advances in technology. Modern roll formers are equipped with sophisticated software that allows for precise engineering simulations. This means that designers can visualize the final product even before physical production begins, ensuring that any potential issues are identified and resolved early in the process.

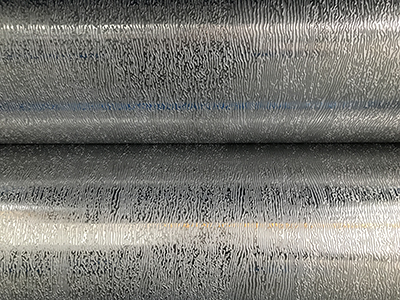

custom custom roll former

Additionally, the integration of automation in custom roll forming has significantly improved production efficiency. Automated systems can operate at high speeds while maintaining the accuracy necessary for custom parts. This has enabled manufacturers to meet rising demand without compromising on quality.

Benefits Across Industries

The applications of custom roll forming extend across various industries. The automotive sector, for example, relies heavily on custom-made parts that adhere to stringent safety standards while also being lightweight and durable. Custom roll forming can produce components such as brackets, supports, and trims that fit seamlessly into the design of a vehicle.

Similarly, in the HVAC (heating, ventilation, and air conditioning) industry, custom roll formers are utilized to create ductwork that precisely fits the architectural designs of buildings. By using custom profiles, HVAC systems can be more efficient, leading to better performance and energy savings.

Sustainability and Efficiency

As industries worldwide shift towards more sustainable practices, the role of custom roll forming becomes even more critical. The precision of the custom roll forming process means that less material is wasted, which not only conserves resources but also reduces the environmental impact of manufacturing. Moreover, the ability to design components that fit perfectly means that systems can operate more efficiently, further contributing to overall sustainability.

Conclusion

In conclusion, custom roll formers represent a significant advancement in the field of manufacturing. Their ability to produce tailored components efficiently and accurately addresses the diverse needs of modern industries. As technology continues to evolve, we can expect custom roll forming to play an increasingly vital role in bringing innovative designs to life while promoting sustainability and efficiency across the board. Embracing the potential of custom roll forming is not just about keeping pace with competition; it’s about redefining what's possible in manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025