custom custom roll former

Custom Roll Formers Tailoring Solutions for Diverse Manufacturing Needs

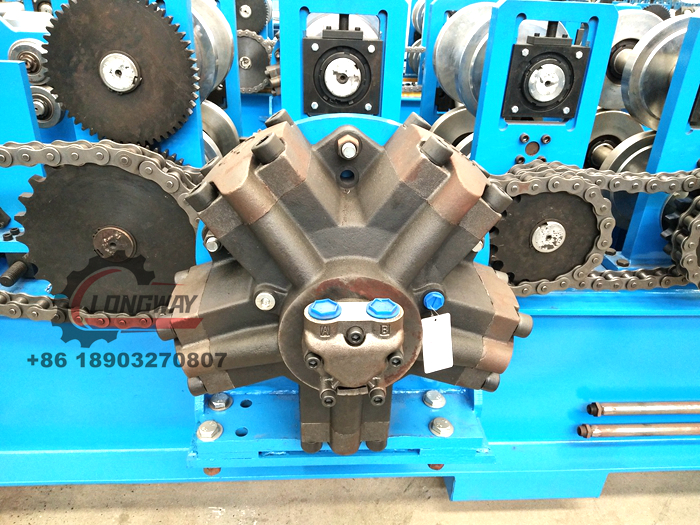

In the modern manufacturing landscape, versatility and precision are paramount. One of the key players in enhancing both is the custom roll former. This specialized equipment is designed to create a wide variety of metal profiles with precision and efficiency, catering to the unique demands of various industries. Whether it’s for construction, automotive, or even furniture design, custom roll formers offer solutions that meet specific operational needs while maintaining high-quality standards.

What is Custom Roll Forming?

Custom roll forming is a continuous bending process that transforms flat metal sheets into complex shapes and profiles. The process involves feeding the metal into a series of rollers that reshape it incrementally. This technique allows for the production of long lengths of material with consistent cross-sectional shapes, making it ideal for high-volume applications.

The custom aspect of roll forming lies in its ability to adapt to the specific requirements of a project. Manufacturers can design unique tooling to create profiles that match exact specifications. This flexibility makes custom roll formers indispensable for businesses looking to innovate and differentiate their products in the competitive market.

Applications of Custom Roll Formers

The applications of custom roll forming are vast and varied. In the construction industry, these machines produce essential components such as metal studs, tracks, and roofing materials. These components not only require the right design but also the strength and durability that custom roll forming delivers.

In the automotive sector, custom roll forming is utilized to manufacture parts such as chassis components, reinforcements, and even decorative trim pieces. The precision of the roll forming process ensures that each part fits perfectly, which is critical in maintaining vehicle safety and performance.

custom custom roll former

The furniture industry has also benefited from custom roll forming. Manufacturers can create unique designs for chair frames, tables, and shelving systems, allowing for greater aesthetic appeal and functionality. The ability to produce lightweight yet strong components is a significant advantage in this sector, making it easier to transport and assemble furniture.

Benefits of Custom Roll Forming

One of the primary advantages of custom roll forming is its efficiency in production. Once the tooling is created, the process can run continuously, leading to reduced labor costs and shorter lead times. This efficiency is particularly beneficial for businesses needing large quantities of custom parts.

Moreover, custom roll forming provides material efficiency. As the process utilizes sheet metal and minimizes scrap by shaping the material rather than cutting it away, manufacturers can save on material costs. This environmentally friendly aspect aligns with modern sustainability initiatives, making custom roll forming a responsible choice.

Another significant benefit is the design flexibility it offers. With the ability to create a broad range of profiles, manufacturers can experiment with new designs and innovations without the heavy investments associated with other manufacturing processes. This innovative edge can be crucial for businesses looking to stay ahead in a rapidly evolving market.

Conclusion

In conclusion, custom roll formers are a vital element in modern manufacturing, providing tailored solutions that can meet the diverse needs of various industries. Their ability to produce high-quality, custom-designed components efficiently and cost-effectively makes them indispensable. As technology advances and the demand for unique metal profiles continues to grow, custom roll forming will undoubtedly play an increasingly significant role in shaping the future of manufacturing. Whether for structural, automotive, or furniture applications, the benefits of custom roll formers position them as a cornerstone of innovative production strategies.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025