Custom Corrugated Sheet Production Machine for Efficient Manufacturing Solutions

Custom Corrugated Sheet Forming Machine Innovating the Future of Manufacturing

In the rapidly evolving landscape of manufacturing, the demand for customized solutions is becoming increasingly vital. Among various manufacturing technologies, the custom corrugated sheet forming machine stands out as a significant innovation, catering to a diverse array of industries. This machine not only enhances production efficiency but also allows for customization, making it a valuable asset for businesses aiming to meet specific market demands.

Understanding Corrugated Sheets

Corrugated sheets are flat panels that consist of a fluted or wavy core sandwiched between two flat liners. This unique structure provides exceptional strength while maintaining a lightweight profile. Such sheets are widely used in packaging, construction, and various other applications due to their durability, insulation properties, and versatility. The ability to create custom sizes and specifications opens up a plethora of opportunities for manufacturers, allowing them to tailor products according to customer requirements.

The Role of Forming Machines

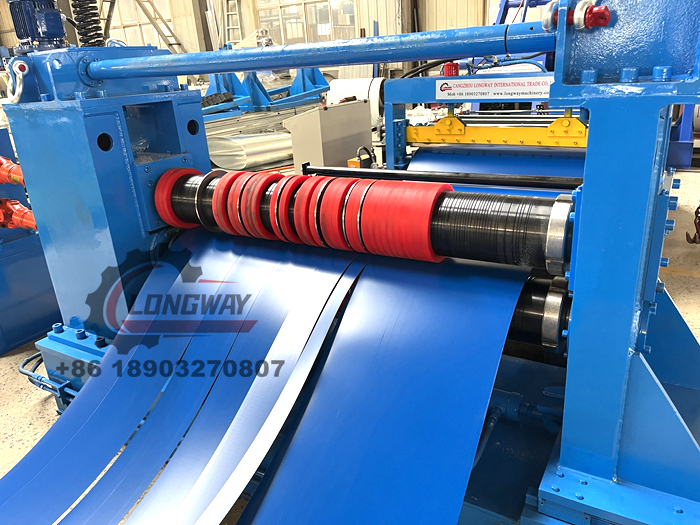

Custom corrugated sheet forming machines are pivotal in the production process of these sheets. These advanced machines facilitate the creation of corrugated sheets in various shapes, sizes, and materials, depending on the specific needs of clients. With the integration of cutting-edge technology, modern forming machines are equipped with features such as programmable controls, automated settings, and enhanced precision, significantly improving output quality and consistency.

The machines operate by taking raw materials, often in the form of flat sheets or rolls, and transforming them into the desired corrugated shape through a series of processes that include heating, molding, and cutting. By utilizing custom settings, manufacturers can produce sheets that conform to specific standards, whether for packaging delicate items or constructing robust structures.

Benefits of Customization

The primary advantage of adopting a custom corrugated sheet forming machine is the capability for customization. Each business has unique requirements based on their end-users, and the ability to modify production processes allows manufacturers to address these needs directly. Customization can include variations in dimensions, material types, and even finishes, thereby enhancing product functionality and appeal.

custom corrugated sheet forming machine

Moreover, customization can lead to cost savings. By producing sheets specifically tailored to customer specifications, manufacturers can reduce waste generated from excess materials or improperly sized products. This not only optimizes resource utilization but also contributes to more sustainable manufacturing practices.

Enhancing Efficiency

In addition to customization, these forming machines significantly improve operational efficiency. Traditional methods of producing corrugated sheets often involve multiple manual processes, which can be time-consuming and prone to errors. In contrast, the automation provided by modern forming machines allows for faster production cycles, reduced labor costs, and minimal downtime.

Additionally, many machines come with features that allow for real-time monitoring and data analysis. Such capabilities enable manufacturers to track production metrics, detect issues promptly, and implement preventive measures. This data-driven approach to manufacturing boosts quality control and ensures that end products meet stringent standards.

Future Prospects

As industries continue to prioritize innovation and sustainability, the demand for custom corrugated sheet forming machines is expected to grow. Advances in technology, particularly in automation and materials science, will further enhance their capabilities. We can anticipate developments such as increased energy efficiency, better adaptability to various materials, and improved user interfaces that simplify the operation of these machines.

Furthermore, the integration of digital manufacturing processes, such as 3D printing and additive manufacturing, may also influence future designs of corrugated sheet forming machines, opening new avenues for customization and production.

Conclusion

The custom corrugated sheet forming machine represents a significant leap forward in manufacturing technology. By providing unparalleled customization and operational efficiency, it is poised to meet the evolving needs of various industries. As businesses continue to embrace innovative manufacturing solutions, these machines will play a crucial role in shaping the future of corrugated sheet production. With a focus on sustainability and efficiency, manufacturers equipped with custom corrugated sheet forming machines will undoubtedly lead the charge in creating more adaptive and responsive supply chains in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025