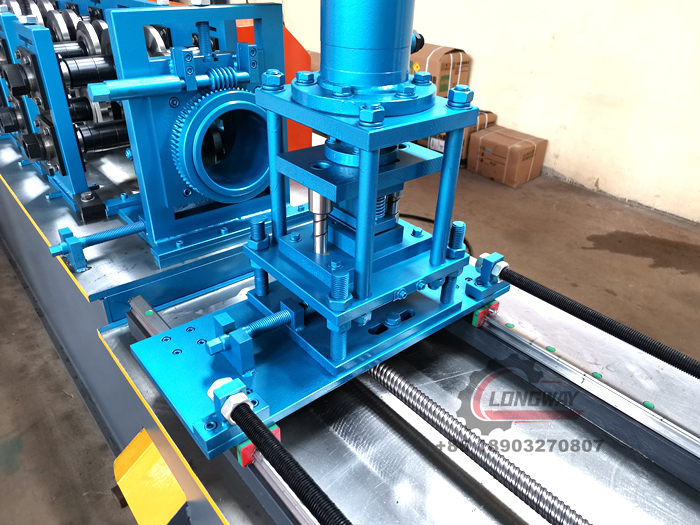

custom batten roll forming machine

Custom Batten Roll Forming Machine A Comprehensive Overview

In the realm of modern manufacturing, the role of roll forming machines has proven to be indispensable, particularly in the creation of custom batten systems. A custom batten roll forming machine is specially designed to produce battens – long, narrow strips used in various applications such as construction, roofing, and fencing. These machines are engineered to meet specific requirements, providing flexibility, efficiency, and precision in manufacturing.

Understanding the Basics

Roll forming is a continuous bending process in which a long strip of metal (usually sheet or coil) is fed through a series of sequentially arranged rollers that progressively shape the material into the desired profile. The custom batten roll forming machine employs this technique to create battens with varying dimensions and styles, tailored to the unique needs of different projects.

Key Components of a Custom Batten Roll Forming Machine

A typical custom batten roll forming machine comprises several essential components, which synergistically work together to achieve high-quality production

1. Feeding System The feeding mechanism ensures that the raw material is fed into the machine accurately and steadily. Proper feeding is crucial for maintaining consistent product quality.

2. Roller Stations The heart of the roll forming machine consists of multiple sets of rollers, each designed to perform specific shaping functions. These rollers can be adjusted to create different batten profiles, allowing for customization.

3. Cutting Mechanism Once the desired length of the batten is achieved, the cutting mechanism comes into play. This can be a shear or a rotary cutter, which ensures clean and precise cuts, reducing waste and enhancing efficiency.

4. Control System Modern roll forming machines are equipped with advanced control systems that monitor production parameters. This enables operators to make real-time adjustments and maintain optimal performance.

custom batten roll forming machine

Benefits of Custom Batten Roll Forming Machines

Investing in a custom batten roll forming machine presents several advantages

- Customization One of the main benefits is the ability to customize products according to specific customer requirements. Whether it's different sizes, shapes, or materials, manufacturers can cater to diverse market needs.

- Efficiency These machines automate much of the production process, significantly increasing output while minimizing manual labor and reducing production costs over time.

- Consistency Since the production is mechanized, the quality of battens produced is consistent. This is crucial in applications where structural integrity is essential.

- Reduced Waste Precision in cutting and forming means less material is wasted, leading to more sustainable manufacturing practices.

Applications of Custom Battens

Custom battens find versatile applications across various industries. In the construction industry, they are used for cladding, architectural frames, and as part of roofing systems. In the agricultural sector, battens are employed in fencing and shade structures. Their aesthetic appeal also makes them popular in interior design, where they can be utilized for decorative purposes.

Conclusion

In summary, a custom batten roll forming machine is a vital tool in the manufacturing landscape, enabling businesses to produce high-quality, tailored battens efficiently. By harnessing the advantages of customization, efficiency, and precision, this machine not only enhances production capabilities but also supports sustainability in manufacturing practices. As industries continue to evolve, the demand for such specialized equipment will undoubtedly grow, paving the way for innovative solutions that meet the challenges of modern production.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025