Custom AG Panel Roll Forming Machine for Efficient Metal Panel Production

The Custom AG Panel Roll Former Revolutionizing the Metal Panel Industry

In recent years, the surge in demand for custom metal panels has transformed various sectors, including agriculture, construction, and manufacturing. As industries seek efficient and reliable solutions for their building requirements, the custom AG panel roll former has emerged as a vital tool, significantly enhancing production capabilities and design flexibility.

Understanding AG Panels

AG panels, short for agricultural panels, are engineered for durability and performance in agricultural environments. These panels are typically made of galvanized steel or aluminum, ensuring they withstand harsh weather conditions, UV exposure, and physical stresses. Their primary applications include roofing and siding for barns, warehouses, and other agricultural structures. The need for these panels stems from their ability to provide a lightweight yet strong solution that can be tailor-made to fit specific architectural designs and functional needs.

The Role of Roll Formers

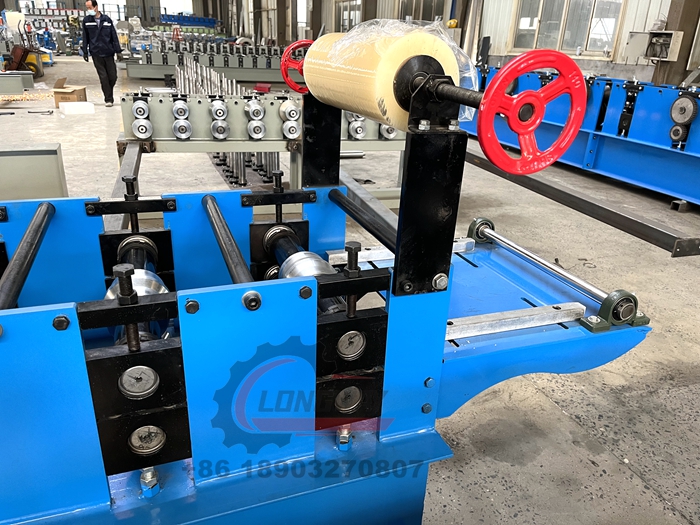

A roll former is a machine that converts flat metal sheets into various profiles by passing the material through a series of rollers that shape it incrementally. This process is crucial in the production of AG panels, as it allows manufacturers to create panels of diverse shapes, sizes, and gauges. The custom AG panel roll former is particularly advantageous because it can be specifically designed to meet the unique requirements of different projects.

With a custom roll forming system, manufacturers can produce panels with distinct features, such as varying rib heights, widths, and lengths. This level of customization is pivotal in meeting the demands of modern construction projects, where standard solutions often fall short. Custom AG panel roll formers not only enhance aesthetic appeal but also ensure optimal performance based on specific installation needs.

Advantages of Custom Roll Formers

1. Efficiency in Production One of the most significant benefits of a custom AG panel roll former is the efficiency it brings to the production line. With advanced automated systems, roll formers can operate at high speeds, reducing lead times and allowing manufacturers to meet tight deadlines. This efficiency translates to lower production costs and improved profitability.

custom ag panel roll former

2. Design Flexibility Custom roll formers provide the flexibility needed in today's market. Designers and architects can collaborate closely with manufacturers to create panels that reflect their visions—be it specific profiles, colors, or finishes. This level of customization is crucial for projects aiming to achieve a unique design while maintaining functional integrity.

3. Material Optimization High-quality roll formers optimize material usage, reducing waste during the production process. Manufacturers can achieve more with less, which is both eco-friendly and cost-effective. Moreover, advancements in technology allow for the use of high-strength materials that further enhance the durability and lifespan of AG panels.

4. Innovation in Design With the rise of smart manufacturing technologies, custom AG panel roll formers can integrate various features into the panels during production. This can include insulation, coatings, and soundproofing elements designed to improve energy efficiency and performance.

Future Trends

As industries continue to evolve, the demand for custom AG panels is expected to rise. Innovations in roll forming technology will likely lead to even more advanced systems that offer enhanced capabilities. We may see greater integration of automation, artificial intelligence, and machine learning, enabling manufacturers to predict trends and adjust production processes accordingly.

Sustainability also plays a crucial role in the future of the metal panel industry. With an increasing focus on environmentally-friendly materials and practices, manufacturers are likely to seek roll forming solutions that support sustainable production while maintaining the high-quality standards expected by clients.

Conclusion

The custom AG panel roll former is undoubtedly a game-changer in the metal panel industry. Its ability to deliver customized solutions, coupled with efficiency and material optimization, positions it as an essential tool for manufacturers. As the market continues to grow, embracing innovation and sustainability will be key to meeting the future demands of construction and agriculture. Through continued advancements in roll forming technology, we can expect the custom AG panel roll former to lead the charge in transforming how we think about metal panels in our built environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025