custom ridge cap roll forming machine

Custom Ridge Cap Roll Forming Machine An Overview

In the world of manufacturing, efficiency and precision are paramount, especially in industries dealing with metal fabrication. One significant innovation that has made waves in this field is the custom ridge cap roll forming machine. Particularly popular in roofing applications, these machines are designed to produce ridge caps—essential components that protect the seams of roofs and enhance their aesthetic appeal.

Understanding the Ridge Cap's Role

Ridge caps are essential in roofing systems, serving to cover the apex where two slopes meet. They not only provide a finished look but also play a critical role in waterproofing and structural integrity. The demand for such products has surged in recent years, prompting manufacturers to seek efficient and reliable solutions for mass production. This is where custom ridge cap roll forming machines come into play.

What is a Custom Ridge Cap Roll Forming Machine?

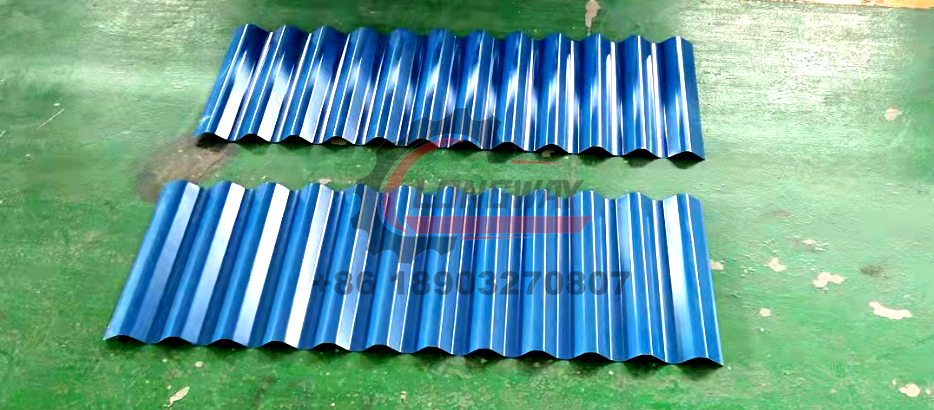

A custom ridge cap roll forming machine is a specialized piece of equipment designed to convert raw metal coils into shaped ridge caps. The process involves feeding the metal material into the machine, which then uses a series of rollers to gradually shape the metal into the desired profile. Customization is a significant aspect of these machines; they can be tailored to produce ridge caps of various sizes, shapes, and designs to meet diverse client specifications.

Benefits of Using Custom Roll Forming Machines

custom ridge cap roll forming machine

1. Precision and Consistency One of the foremost advantages of roll forming technology is the precision it offers. The machinery operates with tight tolerances, ensuring that each ridge cap produced is uniform in appearance and function. This consistency is crucial for roofing applications where any deviation can lead to aesthetic and functional problems.

2. High Production Efficiency Custom ridge cap roll forming machines are designed for high-speed production. Once set up, they can continuously produce large quantities of ridge caps with minimal downtime, making them ideal for businesses looking to increase their output.

3. Material Versatility These machines can work with various materials, including galvanized steel, aluminum, and other alloys, allowing manufacturers to cater to different market requirements. This versatility enables companies to diversify their product offerings.

4. Cost-Effectiveness While the initial investment in a custom roll forming machine may be substantial, the long-term savings are significant. The machine reduces labor costs, minimizes waste material, and cuts down production time, ultimately leading to better profit margins.

5. Sustainability As industries move towards more sustainable practices, roll forming offers an eco-friendly option. The process generates less scrap compared to traditional cutting methods, and many materials used are recyclable.

Conclusion

The custom ridge cap roll forming machine is an invaluable tool for manufacturers in the roofing industry. By investing in this advanced technology, businesses can enhance their production capabilities, ensure high-quality products, and remain competitive in a fast-evolving market. As the demand for sophisticated roofing solutions continues to grow, the significance of custom roll forming machinery will only become more pronounced, driving innovation and excellence within the sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025